Understanding Foundry Sand Specifications

In the metal casting industry, the quality of the product directly relies on the materials used in the casting process. Among these materials, sand plays a crucial role, making it essential to adhere to strict specifications. Foundry sand specifications refer to the detailed criteria that define the physical and chemical properties of sand used in the foundry process. These specifications ensure that the sand performs optimally during mold making, casting, and finishing stages, ultimately affecting the quality of the final product.

Understanding Foundry Sand Specifications

Another important specification is the sand's clay content. Clay acts as a binding agent, helping the sand grains stick together. However, too much clay can lead to issues such as mold defects and poor surface finish. Foundry sands generally require a clay content between 2% and 6%, depending on the specific casting process and metal being poured.

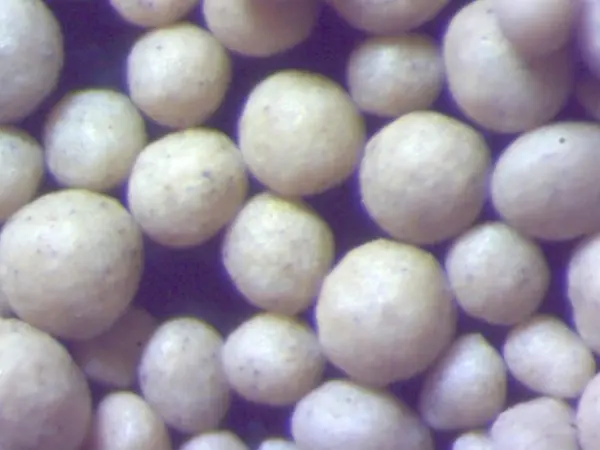

foundry sand specifications

Moisture content is another critical factor, as it affects the sand's ability to bind. Typically, foundry sand is conditioned to contain around 2% to 5% moisture. Too much moisture can lead to steam generation during casting, causing explosive failures, while too little moisture can result in weak molds.

Chemical composition is equally vital; presence of impurities like iron oxide, which can alter the metal's properties, must be minimized. Specifications often require that the total iron content in molding sand should not exceed 2%. Additionally, other contaminants such as sulfur and phosphorus should also be monitored, especially when casting ferrous metals, as these elements can degrade the overall quality of the steel produced.

In recent years, there has been a growing trend toward using reclaimed sand. Specifications for reclaimed sand often revolve around its consistency and cleanliness. The procedures to reclaim sand must ensure that the material retains the desired properties of fresh sand, including appropriate grain size distribution, adequate bonding agents, and minimal contaminant levels.

In conclusion, adherence to foundry sand specifications is vital for producing high-quality castings. Understanding the physical and chemical properties of foundry sand helps ensure that the molds made are strong and reliable, leading to superior casting performance. As industries evolve, ongoing research and development into new materials and processing methods will further refine these specifications, promoting innovations in foundry practices and resulting in better products in the long run.

Post time:oct. . 30, 2024 21:37

Next:ceramic sand