The Difference Between Sand Casting and Investment Casting

Casting is a manufacturing process where material is poured into a mold to create a desired shape. Two widely used casting methods are sand casting and investment casting. While both techniques serve the same fundamental purpose, they differ significantly in their processes, applications, and the quality of the final product.

Process Overview

Sand casting is one of the oldest and most versatile casting processes. It involves creating a mold by packing sand around a pattern that resembles the object to be cast. The mold is then removed, and molten metal is poured into the cavity created by the pattern. After the metal cools and solidifies, the sand mold is broken away to reveal the final product. This method is cost-effective for producing large parts and is highly suitable for a variety of metals.

Investment casting, also known as lost-wax casting, is a more intricate process. This method involves creating a wax pattern of the desired shape, which is then coated with a ceramic material to form a mold. Once the mold is hardened, the wax is melted away, leaving a precise cavity for the molten metal. Investment casting allows for a high degree of dimensional accuracy and surface finish, making it ideal for complex geometries and detailed designs.

Quality and Precision

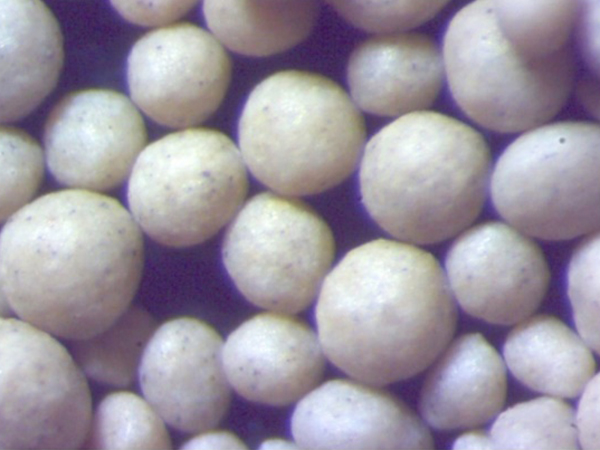

difference between sand casting and investment casting

One of the standout differences between these two methods is the level of precision. Sand casting typically produces parts with tolerances of about ±0.5 mm, which may be sufficient for many applications. However, investment casting offers tolerances of ±0.1 mm or even better, making it suitable for high-precision components such as aerospace and medical devices. The smoother surface finish of investment casting also reduces the need for extensive machining after the casting process.

Applications

The choice between sand casting and investment casting often depends on the specific requirements of the project. Sand casting is predominantly used in industries that require large, durable parts, such as automotive and heavy machinery. Its ability to produce sizeable components in a cost-effective manner emphasizes its reliability in those sectors.

In contrast, investment casting is favored in industries where precision and intricate designs are paramount. This includes aerospace, military, and medical fields, where components often need to meet stringent quality standards. The additional cost associated with investment casting is often justified by the quality and performance of the finished product.

Conclusion

In summary, while both sand casting and investment casting are effective methods for producing cast parts, their differences in processes, precision, and applications make them suitable for distinct manufacturing scenarios. Sand casting is advantageous for large and robust items, while investment casting excels in producing complex, high-precision components. Understanding these differences is crucial for manufacturers when selecting the appropriate casting method for their projects.

Post time:sept. . 22, 2024 07:04

Next:sand casting processes