3D Printed Sand Casting Revolutionizing the Manufacturing Industry

In recent years, additive manufacturing has significantly transformed various sectors, and one of the most compelling applications is the combination of 3D printing technology with sand casting. This innovative approach represents a paradigm shift in the manufacturing landscape, especially in the fields of metallurgy and manufacturing engineering. The integration of 3D printed sand molds in the casting process enhances efficiency, reduces material waste, and opens up new design possibilities.

Understanding Sand Casting

Sand casting is one of the oldest and most widely used metal casting processes. Traditionally, it involves creating a mold from sand into which molten metal is poured. The process is simple yet effective, providing excellent casting surface quality and allowing for complex shapes. However, conventional sand casting methods can be labor-intensive and time-consuming, often requiring multiple steps to create patterns.

Historically, manufacturers relied on wooden or metal patterns to create molds, which can be both expensive and time-consuming to produce. Moreover, once patterns are made, any changes to the product design typically necessitate the creation of new patterns, leading to increased costs and prolonged lead times.

The Role of 3D Printing in Sand Casting

The integration of 3D printing technology into sand casting addresses many of these traditional challenges. By employing 3D printed sand molds, manufacturers can streamline the process and incorporate more intricate designs without the limitations imposed by traditional pattern-making techniques.

3D printing offers the ability to create highly detailed molds quickly and efficiently. With this technique, designers can iterate and modify the mold design digitally before printing it, significantly reducing the time from concept to production. This rapid prototyping capability allows for immediate adjustments, reducing costly delays that are common in traditional methods.

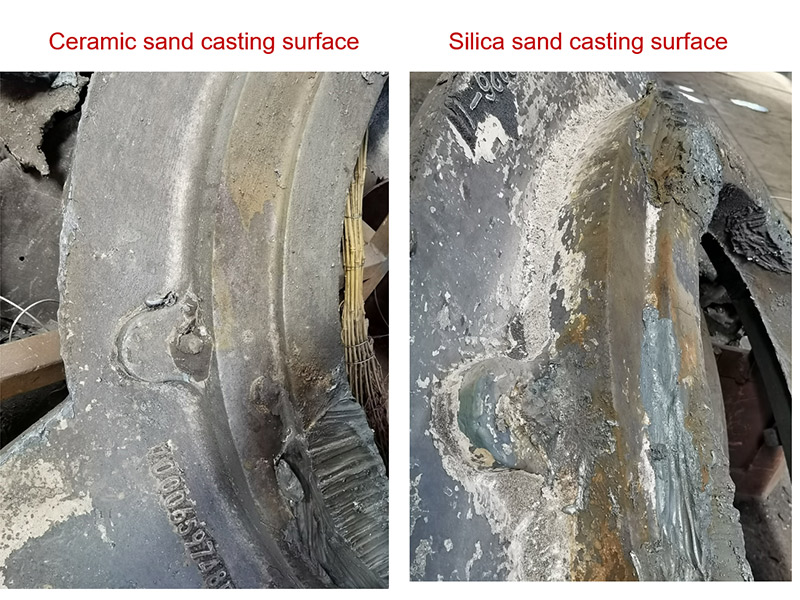

Moreover, the materials used in 3D printing sand molds, typically a mixture of sand and a binder, allow for exceptionally precise molds that can capture intricate geometries and patterns. As a result, the final cast products often exhibit higher quality and reduced need for post-processing.

Benefits of 3D Printed Sand Casting

3d printed sand casting

1. Cost Efficiency By eliminating the need for traditional patterns and associated labor costs, the use of 3D printed sand molds can lead to significant cost savings. The ability to quickly produce molds also reduces lead time, allowing for speedy project turnarounds.

2. Design Flexibility Designers are no longer limited by the constraints of traditional mold-making techniques. Complex internal features, lightweight structures, and customized designs can easily be manufactured, promoting innovation in product development.

3. Sustainability The additive nature of 3D printing results in less material waste compared to traditional subtractive manufacturing methods. Furthermore, many companies are exploring the use of recyclable materials in their 3D printing processes, contributing to more sustainable manufacturing practices.

4. Enhanced Production The speed of 3D printing accelerates the overall production cycle. Manufacturers can respond to market demands more swiftly, producing shorter production runs without the significant upfront investment typically required for traditional tooling.

Challenges and Future Perspectives

While there are numerous advantages to 3D printed sand casting, challenges remain. The material properties of 3D printed sand molds need to be thoroughly evaluated to ensure they can withstand the stresses of molten metal. Additionally, industry standards and certifications for using 3D printed molds in commercial applications are still evolving.

As technology continues to advance, we expect to see further developments in materials and processes that enhance the viability of 3D printed sand casting. The ongoing collaboration between software developers, material scientists, and manufacturing engineers will likely lead to improvements in mold quality and printing efficiency.

Conclusion

3D printed sand casting is an exciting advancement that holds great promise for the future of manufacturing. By marrying traditional casting techniques with modern additive manufacturing, we can expect to see a more efficient, cost-effective, and innovative approach to metal production. As this technology matures, it will undoubtedly continue to reshape the manufacturing landscape, paving the way for applications and possibilities previously thought unattainable.

Post time:nov. . 11, 2024 16:42

Next:materials used in sand casting