Sintering Sand A Key Component in Modern Manufacturing

Sintering is a widely used process in the manufacturing industry, particularly in the fields of ceramics, metals, and various composite materials. Among the critical materials that facilitate sintering is sintering sand. This specialized sand plays a vital role in shaping and strengthening products through its unique physical and chemical properties. Understanding the significance of sintering sand not only highlights its importance but also unveils the intricate processes involved in modern manufacturing.

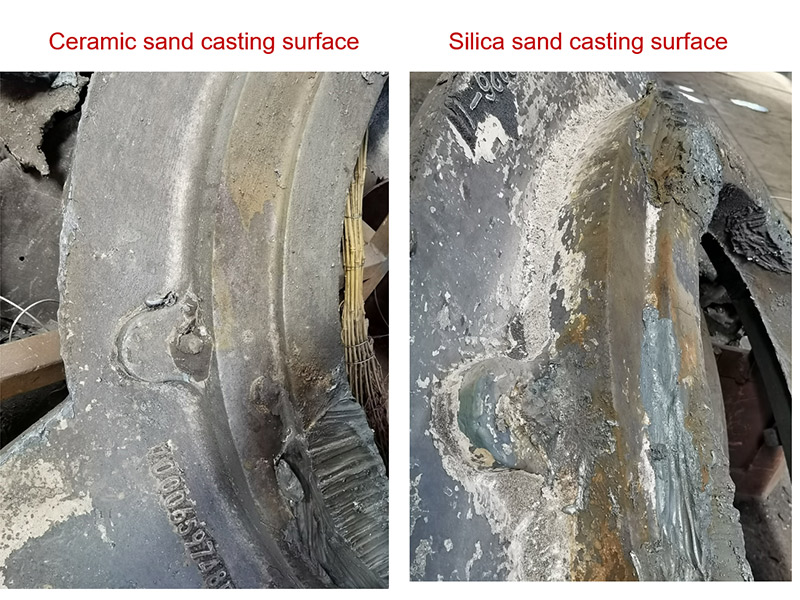

Sintering sand is characterized by its fine grain size, high melting point, and excellent thermal stability. These features make it an ideal medium for the sintering process, which involves heating powdered materials to a temperature below their melting point, allowing them to fuse together. The use of sintering sand enhances the mechanical properties of the final product, ensuring that it exhibits superior strength, durability, and resistance to wear and tear.

In various industrial applications, including the production of tiles, bricks, and metal components, sintering sand serves as a crucial additive in the sintering mix

. By providing a stable base for the powdered materials, sintering sand helps to promote homogeneity in the mixture, which is essential for achieving consistent results. Furthermore, the sand aids in controlling the thermal conductivity of the sintering mixture, allowing for more uniform heating and improved quality of the final product.sintering sand

The importance of sintering sand extends beyond its mechanical properties; it also plays a vital role in the reduction of defects during the sintering process. By minimizing the formation of voids and improving the packing density of the powder mixture, sintering sand helps to create a more solid and durable end product. This is particularly important in industries that require high precision and reliability in their manufactured goods, such as aerospace, automotive, and medical device sectors.

Moreover, the selection of appropriate sintering sand is critical for optimizing production efficiency and reducing costs. Different types of sintering sands are available, each with its unique properties tailored to specific applications. Manufacturers must carefully consider factors such as particle size, shape, and thermal properties when choosing the right sintering sand for their needs. This not only impacts the quality of the final product but also influences overall production timelines and costs.

In conclusion, sintering sand is an essential material in today’s manufacturing landscape, playing a crucial role in enhancing the properties of various products through the sintering process. Its ability to improve mechanical strength, reduce defects, and promote uniformity makes it indispensable in numerous industries. As technology continues to advance, the development and optimization of sintering sand will remain a key focus for manufacturers seeking to innovate and improve the performance of their products. Understanding the significance of sintering sand not only brings to light its pivotal role in production but also emphasizes the intricate interplay of materials that drives modern manufacturing forward.

Post time:Oct . 07, 2024 12:23

Next:3d printing patterns for sand casting