The 3D Sand Printing Process A Revolutionary Approach in Manufacturing

The advent of 3D printing has revolutionized various industries, and one of the most exciting developments within this realm is the 3D sand printing process. This innovative technique utilizes sand as the primary material to create intricate and complex designs, making it particularly advantageous in the fields of manufacturing, construction, and sculpture. By understanding the basic principles of sand printing and its applications, we can appreciate its potential impact on modern production methods.

The 3D Sand Printing Process A Revolutionary Approach in Manufacturing

One of the major advantages of 3D sand printing is its efficiency in creating molds for metal casting. Traditionally, molding processes involve the use of patterns made from wood or metal, which can be expensive and time-consuming to produce. With sand printing, molds can be produced directly from CAD (computer-aided design) models, significantly reducing lead times and costs. This process not only streamlines the production workflow but also allows for rapid prototyping, enabling manufacturers to test and iterate on designs quickly.

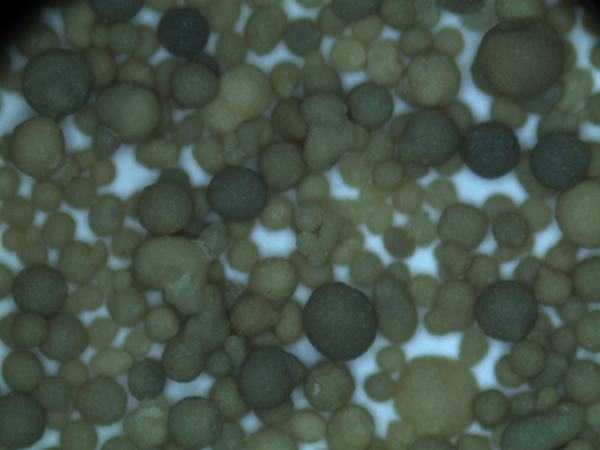

3d sand printing process

Additionally, the use of sand as a printing material contributes to the sustainability of the process. Sand is abundant and can be recycled numerous times, reducing waste and minimizing environmental impact. Unlike some traditional manufacturing methods that generate substantial waste, 3D sand printing is more resource-efficient. The ability to produce customized parts on-demand further reduces the need for extensive inventory, aligning with modern manufacturing practices that emphasize lean production.

The applications of 3D sand printing are vast and varied. In the automotive industry, it is being used to create lightweight and complex components that improve fuel efficiency. In aerospace, the technology allows manufacturers to produce intricate parts that meet stringent safety standards while minimizing weight. Additionally, the construction sector is beginning to harness the power of sand printing to create innovative structures and elements that were once considered impossible.

Moreover, the artistic community has embraced 3D sand printing as a means of expression. Sculptors can utilize this technology to manifest their visions into tangible forms, experimenting with shapes and designs that challenge traditional sculpture methods. The ability to create large-scale art installations using sand has opened new avenues for creativity and expression.

In conclusion, the 3D sand printing process is transforming the landscape of manufacturing and art. By merging innovative technology with traditional materials, it offers unprecedented design flexibility, efficiency, and sustainability. As industries continue to explore the potential of this process, we are likely to see even more remarkable advancements that will further shape our understanding of production and creativity in the 21st century. As we move forward, the integration of 3D sand printing into various sectors will undoubtedly pave the way for a more innovative and sustainable future.

Post time:paź . 08, 2024 00:22

Next:buhangin para sa paghahagis ng metal