The Role of Sintering in Sand Processing

Sintering is a widely recognized manufacturing process utilized in various industries, particularly in the production of ceramics and metals. Among its less-discussed applications is the treatment of sand, especially in contexts like foundry operations and the manufacturing of refractory materials. Sintering sand has become a focal point for innovation, enhancing properties that improve performance and functionality in various applications.

Understanding Sintering

Sintering is the process of compacting and forming a solid mass of material through heat or pressure without reaching the melting point of the material. The technique involves the diffusion of atoms and helps to create a more compact and denser structure. This process can significantly influence the physical and chemical properties of the material, making it essential in optimizing sand characteristics for specific applications such as casting molds and cores.

Sintering Sand in Foundry Applications

In the foundry industry, sand is a critical material used for making molds and cores for metal casting. Traditionally, sand is mixed with a binder to enhance its cohesiveness and ability to hold shape during the casting process. However, introducing sintering techniques to sand processing can lead to improved durability, thermal stability, and dimensional accuracy of the molds.

Sintered sand has a unique structure that enhances its ability to withstand high temperatures encountered during metal pouring. When subjected to heat, the particle surfaces begin to bond, creating a stronger matrix that resists deformation and cracking. This characteristic is vital when casting metals with high melting points, as it ensures the integrity of the mold throughout the casting cycle.

Advantages of Sintering Sand

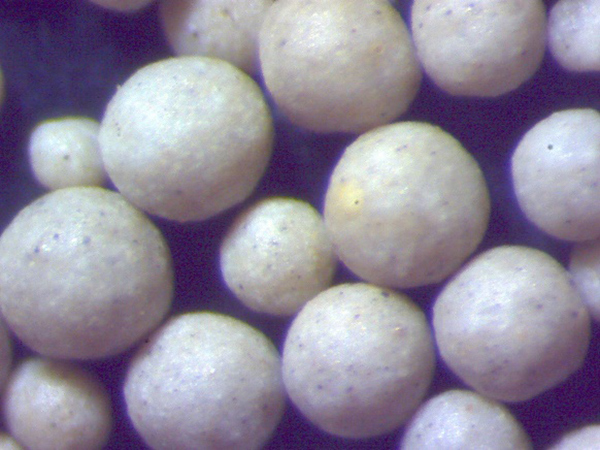

sintering sand

1. Enhanced Mechanical Properties Sintering can significantly increase the compressive strength and thermal resistance of sand. This is particularly vital in applications involving heavy metal casts, where the mold must maintain its shape under severe thermal stress.

2. Reduced Binder Requirements With enhanced cohesion through sintering, the quantity of binders needed can be reduced. This not only lowers material costs but also decreases the risk of binder-related defects in the cast metal, leading to higher quality finished products.

3. Improved Surface Finish Sintering helps produce finer particle boundaries and enables the formation of a more uniform mold surface. This attribute is crucial for achieving smoother finishes on cast items, reducing the need for secondary finishing processes.

4. Sustainability The implementation of sintered sand can contribute to sustainability efforts within foundries. By minimizing binder usage and enhancing mold qualities, it potentially reduces waste and energy consumption during the manufacturing process.

Applications Beyond Foundries

While the foundry industry benefits immensely from the sintering of sand, its applications extend into other fields. The construction industry, for instance, is exploring the use of sintered sand in producing durable construction materials. Additionally, the ceramics sector can leverage sintered sand for producing tiles and decorative objects with improved strength and aesthetics.

Conclusion

Sintering sand is an innovative approach that addresses several challenges faced in various industries, particularly in foundries. The advantages it offers—in terms of mechanical properties, reduced binder usage, enhanced surface finishes, and sustainability—underscore its potential as a game changer in sand processing. As industries continually seek to improve efficiency and product quality, the role of sintering in enhancing sand and its myriad applications is set to grow. The ongoing research and implementation of advanced sintering techniques hold promise for richer, more refined materials that can meet the evolving demands of modern manufacturing.

Post time:ਨਵੰ. . 29, 2024 20:27

Next:3D Kum Döküm Uygulamaları ve Yenilikçi Tasarım Süreçleri Hakkında Bilgiler