Molding Sand for Metal Casting An Essential Component in Foundry Operations

Molding sand plays a crucial role in the metal casting process, serving as the medium in which metal is shaped and solidified. It is a carefully formulated mixture that provides the necessary properties to create high-quality metal castings. The effectiveness of molding sand directly influences the final product's dimensional accuracy, surface finish, and overall integrity.

Molding Sand for Metal Casting An Essential Component in Foundry Operations

One of the essential attributes of molding sand is its ability to withstand high temperatures. When molten metal is poured into the sand mold, temperatures can reach upwards of 1,500 degrees Celsius (2,732 degrees Fahrenheit). The molding sand must not only resist deformation but also effectively absorb and dissipate these heat levels to prevent damage to the mold itself.

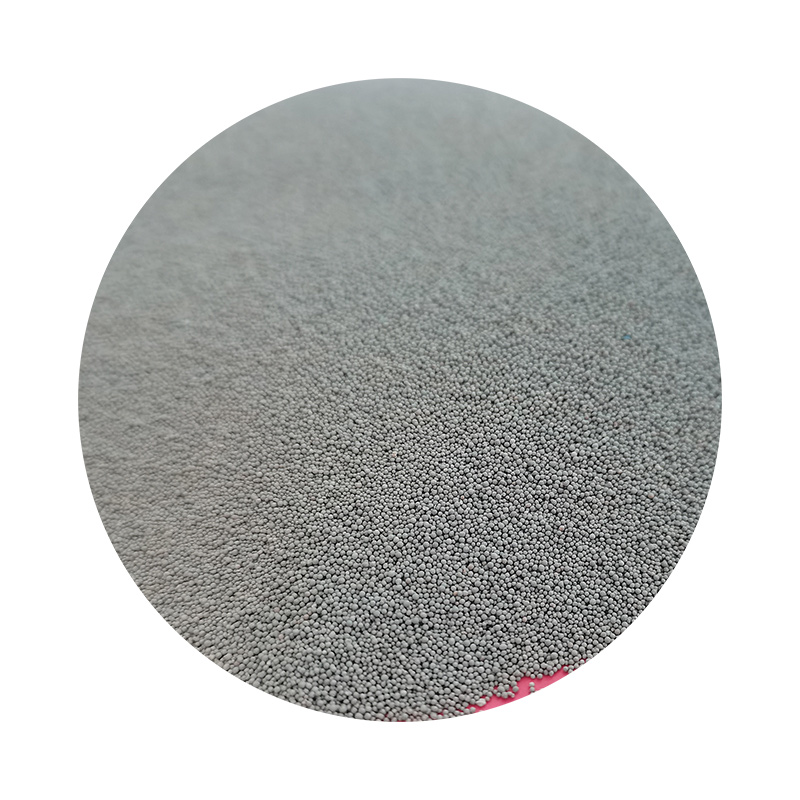

molding sand for metal casting

There are several types of molding sand, each tailored for specific casting requirements. Green sand, a mixture of silica sand, clay, and water, is the most common type used in foundries due to its versatility and cost-effectiveness. It allows for the easy production of molds and can accommodate intricate designs. Resin-bonded sand is another variant, which utilizes synthetic resins as a binding agent. This type of sand is favored for its superior dimensional accuracy and ability to produce smoother surface finishes.

The choice of molding sand significantly impacts the casting process. For example, the use of finer sand grains results in a smoother surface finish, which is essential for components that require minimal post-casting machining. Conversely, coarser sand can facilitate easier removal of the mold and is suitable for larger castings where surface finish is less critical.

In addition to these factors, proper handling and preparation of molding sand are vital for successful casting operations. The sand must be regularly tested for quality, including moisture content, grain size distribution, and bonding strength. Foundries often recycle molding sand to enhance sustainability, but this process also requires diligent monitoring to maintain optimal sand properties.

In conclusion, molding sand is an indispensable element in the metal casting industry, providing the foundation for producing complex and high-precision metal components. Understanding the properties and types of molding sand can help foundries optimize their casting processes, ensuring high-quality products that meet industry standards. As technology evolves, advancements in molding sand formulations and recycling practices continue to enhance the efficiency and sustainability of metal casting.

Post time:ਸਤੰ. . 22, 2024 04:23

Next:foundry sand service