Lost Foam Casting Coating An Overview

Lost foam casting is a specialized manufacturing process utilized primarily in metalworking and foundry applications. This innovative technique allows for the creation of complex metal components with high precision and excellent surface finish. One critical aspect of this process is the coating used on the foam pattern, which plays a vital role in ensuring the quality and integrity of the final product.

Lost Foam Casting Coating An Overview

One of the key benefits of using a coating in lost foam casting is to control the thermal properties of the mold. The coating helps to insulate the foam pattern, allowing it to be used for a longer duration under extreme heat. This ensures that the molten metal pours in smoothly, filling all areas of the pattern. If the coating is inadequate or improperly applied, it could lead to defects such as incomplete casts or excessive porosity in the final component.

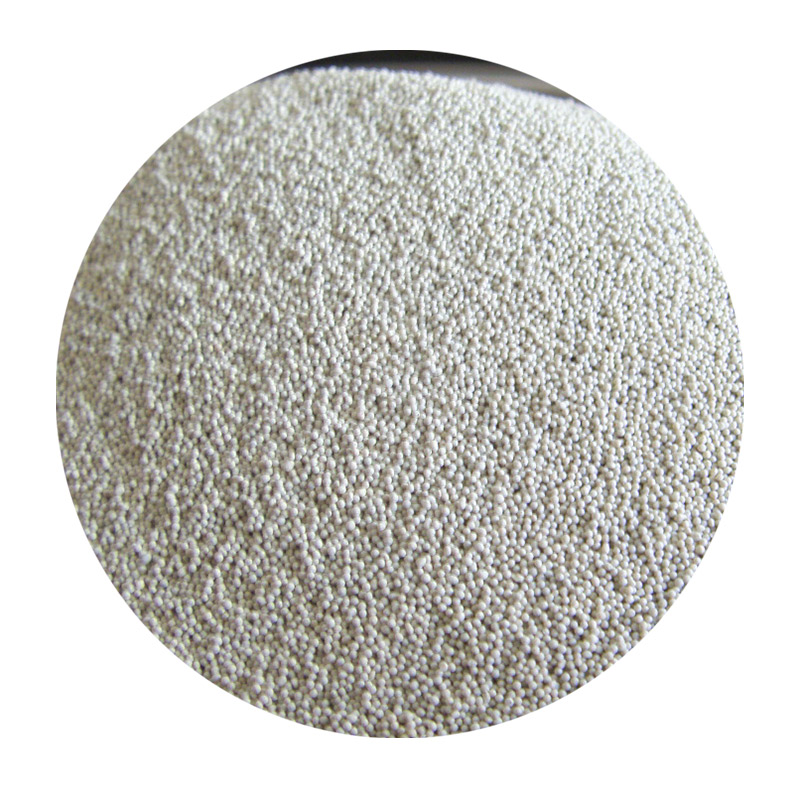

lost foam casting coating

Moreover, the coating serves to prevent the molten metal from reacting with the foam and protects against contamination, which could compromise the quality of the metal. Proper application techniques such as dipping, spraying, or brushing are essential to achieve a uniform layer of coating. Additionally, the thickness and composition of the coating can significantly influence the casting process and the final properties of the metal, such as strength and durability.

In terms of innovation, ongoing research aims to improve the materials used in lost foam casting coatings. The development of advanced ceramic coatings, for instance, offers enhanced performance in terms of heat resistance and structural integrity. Manufacturers are also exploring eco-friendly alternatives to traditional materials to reduce environmental impact without sacrificing quality.

In conclusion, the coating used in lost foam casting plays a critical role in determining the success of the casting process. By providing thermal insulation, preventing contamination, and ensuring dimensional accuracy, the right coating greatly impacts the overall quality of the final metal component. As technological advancements continue, the future of lost foam casting looks promising, with improved coating materials leading the way for even more complex and high-quality cast products. With a keen focus on innovation, the industry can expect to meet the increasing demands for precision and efficiency in metal manufacturing.

Post time:ਨਵੰ. . 15, 2024 13:27

Next:what materials are used for sand casting