What is Sand Casting Used For?

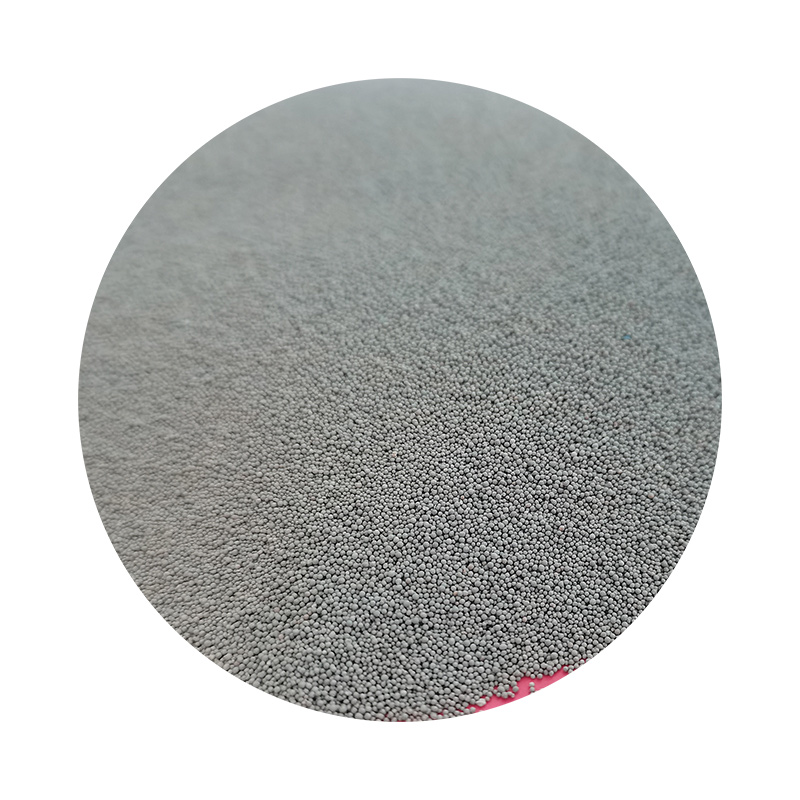

Sand casting, one of the oldest and most versatile casting methods, is widely utilized in various industries for its ability to create complex shapes and components. This process involves creating a mold from sand, which is then used to form metal parts after pouring molten metal into the mold cavity. The versatility, cost-effectiveness, and accessibility of materials associated with sand casting make it a preferred choice for many applications across different sectors.

Applications in the Automotive Industry

One of the most significant applications of sand casting is in the automotive industry. Manufacturers use this process to produce engine blocks, cylinder heads, and various other components that require strength and durability. The complexity involved in automotive designs often necessitates the use of sand casting because it allows for intricate shapes and internal channels that would be challenging to achieve with other manufacturing processes. Additionally, the ability to cast large parts in a single piece significantly reduces assembly time and costs.

Aerospace Components

Another critical area where sand casting is employed is in the aerospace sector. Components such as turbine housings, structural frames, and support brackets are often produced using sand casting techniques. The aerospace industry demands high-performance parts that can withstand extreme conditions, and sand casting allows engineers to create lightweight structures with the necessary strength-to-weight ratios. Furthermore, this process enables the use of advanced metal alloys, which are essential for high-stress applications.

Artistic and Sculptural Uses

Sand casting is not limited to industrial applications; it is also widely used in art and sculpture. Artists frequently use sand casting to create metal sculptures or decorative pieces. The ability to manipulate the sand mold allows for the creation of unique designs, and the final product can be finished with various surface treatments to achieve different aesthetic effects. This artistic application illustrates the versatility of sand casting beyond traditional manufacturing.

what is sand casting used for

Agricultural Machinery

In the agricultural sector, sand casting is essential for producing components for various types of machinery. Parts such as gears, housings, and frames for tractors and harvesters are commonly formed using this method. The durable components are designed to endure harsh conditions and heavy usage, highlighting the reliability of sand casting in producing agricultural machinery that can sustain demanding operations and environments.

Electrical Equipment

Sand casting is also crucial in making housings for electrical equipment and components. This includes items like motor housings, transformer cases, and other enclosures that require robust and protective structures. Due to the electrical and thermal properties of various alloys, manufacturers can produce components that meet specific requirements for efficiency and safety.

Marine Applications

The marine industry makes extensive use of sand casting to manufacture components like propellers, pump housings, and various fittings. These parts must resist corrosion and withstand harsh marine environments, making the selection of appropriate materials and casting techniques vital. Sand casting allows for the creation of intricate designs that are not only visually appealing but also functional and resilient.

Conclusion

In conclusion, sand casting is a versatile and indispensable fabrication method used in numerous industries ranging from automotive to aerospace and beyond. Its ability to create complex shapes with durable materials makes it an ideal choice for many applications. As technology continues to evolve, so will the methods of sand casting, enhancing its capabilities and expanding its uses across emerging industries. Whether for industrial production, artistic endeavors, or specialized applications, sand casting remains a cornerstone of metalworking and manufacturing.

Post time:Nov . 19, 2024 22:16

Next:gold sand price