Sand Casting Technology A Comprehensive Overview

Sand casting, one of the oldest and most versatile manufacturing processes, has been a cornerstone in metalworking for centuries. This technique allows for the production of complex metal parts with excellent dimensional accuracy and surface finish. In this article, we will explore the fundamentals of sand casting technology, its advantages, applications, and modern advancements that enhance its capabilities.

Fundamentals of Sand Casting

At its core, sand casting involves the creation of a mold from sand, which is then used to form metal objects. The process begins by creating a pattern, a replica of the final product, which is usually made from metal or plastic. This pattern is embedded in a mixture of sand and a bonding agent, typically clay. The mixture is compacted around the pattern to create a mold cavity.

Once the mold is formed and the pattern removed, molten metal is poured into the cavity. After the metal has cooled and solidified, the sand mold is broken apart to retrieve the cast object. The simplicity and flexibility of this process make it suitable for a wide range of metals, including aluminum, iron, and bronze.

Advantages of Sand Casting

One of the primary advantages of sand casting is its cost-effectiveness. The materials required—sand and a bonding agent—are relatively inexpensive, and the process does not necessitate elaborate machinery, making it accessible to small and medium-sized enterprises. Additionally, sand molds can be reused multiple times, further reducing costs.

Another significant advantage is the ability to produce large parts or small batches of various shapes, which might be difficult or even impossible with other casting methods. The adaptability of sand casting allows for intricate designs and larger components, making it a preferred choice in industries like automotive and aerospace.

Applications of Sand Casting

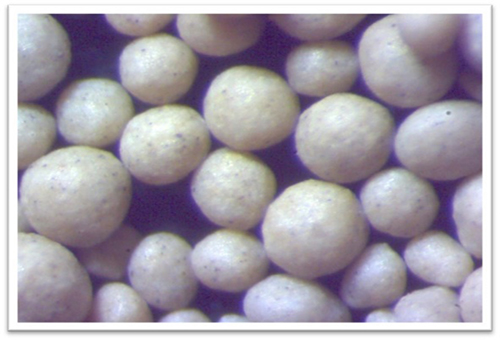

sand casting technology

Sand casting finds applications in numerous sectors due to its versatility. In the automotive industry, it is used to produce engine blocks, transmission cases, and other critical components. The ability to create complex geometries and handle high melting temperatures makes sand casting ideal for these demanding applications.

In the aerospace sector, sand casting is utilized to manufacture parts that require high strength-to-weight ratios and excellent dimensional stability. Components like brackets, housings, and even larger structural pieces are often produced using this technology.

Furthermore, infrastructure projects benefit from sand casting in creating components for construction equipment, pipelines, and machinery. The durability and reliability of sand-cast products are crucial for these demanding applications.

Modern Advancements in Sand Casting

While traditional sand casting methods have stood the test of time, modern advancements have significantly enhanced this technology. The integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) tools allows for greater precision in pattern making and mold design. Advanced simulation software can predict casting defects, enabling engineers to make necessary adjustments before the actual production begins.

Additionally, the introduction of 3D printing technology in sand mold production has revolutionized the process. With 3D-printed sand molds, manufacturers can create complex geometries more effectively and with reduced lead times. This innovation not only increases production efficiency but also broadens the range of designs that can be produced.

Sustainability is another area where sand casting is evolving. The industry is increasingly looking for ways to reduce waste and recycle materials. The use of reclaimed sand and eco-friendly binders is becoming more common, which helps mitigate the environmental impact of the casting process.

Conclusion

Sand casting technology remains a vital manufacturing process, blending traditional techniques with modern innovations to meet the demands of today’s industries. Its cost-effectiveness, ability to produce complex shapes, and adaptability make it an indispensable choice for metal fabrication. As the industry continues to evolve, the integration of advanced technologies and sustainability practices will likely shape the future of sand casting, ensuring it stays relevant in an increasingly competitive landscape. Whether in automotive, aerospace, or construction, sand casting will continue to play a crucial role in producing high-quality components for years to come.

Post time:Dec . 12, 2024 10:22

Next:heath ceramics sand