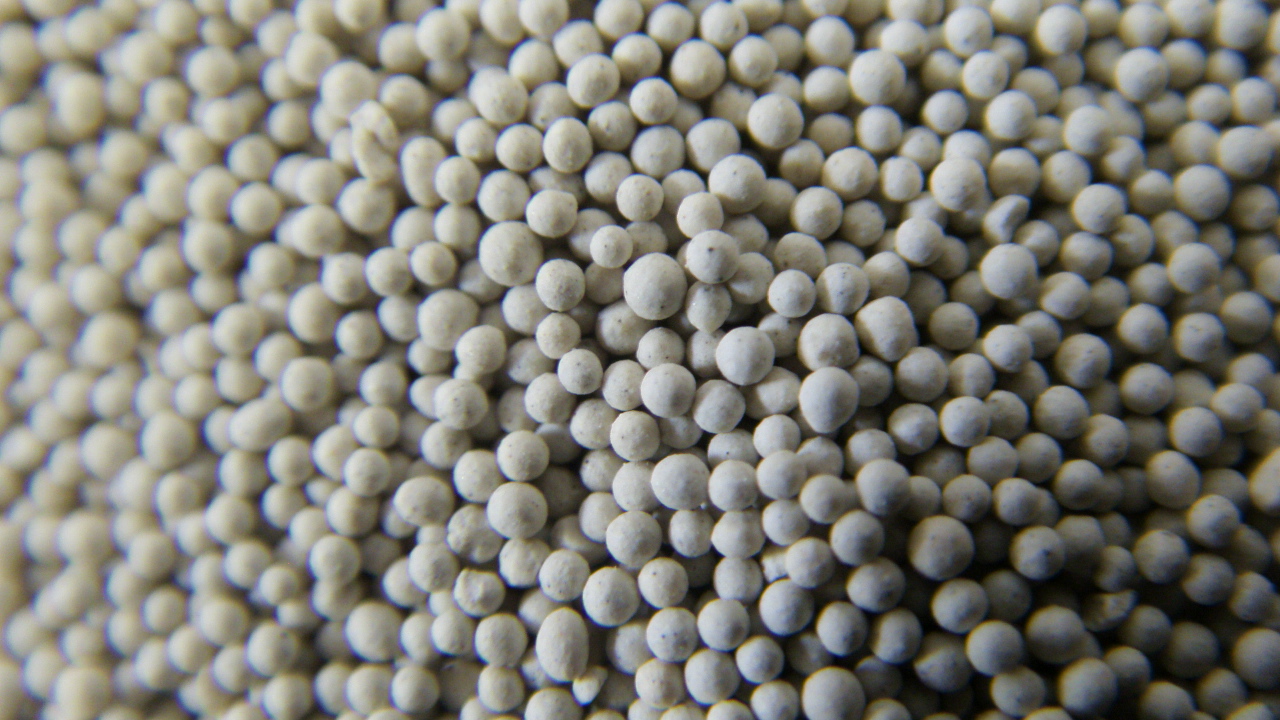

Among the various types of casting sand available, green sand and dry sand are the two most common. Green sand, rich in clay, is lauded for its versatility and cost-effectiveness. It is especially favored in mass-production settings. Dry sand, in contrast, is typically used for larger castings as it can be molded into more stable structures. Each type of sand offers unique benefits depending on the scale and specificity of the casting project. To gain expertise in the field, consider consulting seasoned professionals who possess a wealth of experience in selecting and using different types of casting sand. These experts can provide invaluable insights into optimizing the casting process while minimizing material waste. Many professionals recommend starting with small pilot projects to test different sands before committing to large-scale production. When purchasing metal casting sand, trustworthiness of the supplier is essential. Reliable suppliers typically provide comprehensive details about their products, including material origins and quality certifications. They should also offer transparent customer services and support. Engaging with reputable suppliers ensures not only a consistent supply of material but also peace of mind that the sand will perform as expected under industrial conditions. A frequently asked question is where to purchase metal casting sand. With the proliferation of e-commerce, many companies offer casting sand online; however, it is crucial to verify the legitimacy of these sources. Platforms like eBay or specialized industrial websites often display user reviews, providing an initial benchmark for reliability and quality assurance. Overall, while the choice and purchase of metal casting sand may seem like a minor decision in the grand scheme of casting, its impact on the output quality cannot be overstated. By emphasizing due diligence in product selection, forging relationships with knowledgeable experts, and engaging trustworthy suppliers, manufacturers can significantly improve their casting results. Navigating the intricacies of metal casting sand effectively combines experience, professional insights, authority in the material's applications, and unwavering focus on quality assurance to ensure successful casting endeavors. Post time:Jan . 26, 2025 05:03

Next:casting sand for sale