Understanding the Sand Foundry Process

The sand foundry process is a pivotal method in metal casting, widely employed in various industries to produce a plethora of metal components. This process is celebrated for its versatility, efficiency, and ability to create complex geometries with high precision, making it an integral part of modern manufacturing.

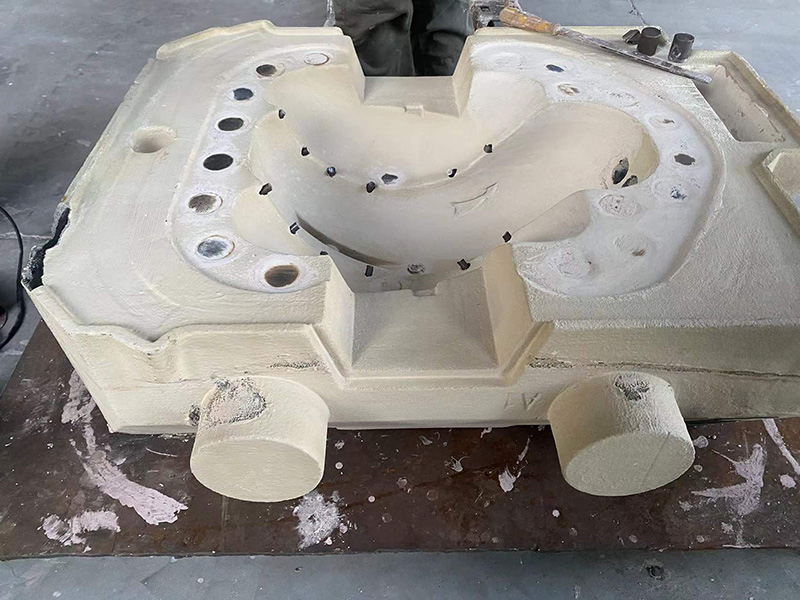

At the heart of the sand foundry process is the use of sand as a primary mold material

. The sand, typically mixed with a binder to enhance its cohesiveness, is compacted around a pattern that represents the final product. Patterns can be made from various materials such as metal, wood, or plastic, and they are designed to be slightly larger than the final casting to accommodate shrinkage during cooling.Once the pattern is set, a mold is formed by compacting the sand around it. This operation often involves two halves to facilitate the removal of the pattern after the mold is created. Additional features such as vents and gates are incorporated into the mold design to ensure proper flow of molten metal, as well as to allow gases to escape during the pouring process.

sand foundry process

After the mold is prepared, it is ready for the metal casting. Molten metal, usually produced by melting alloys in a furnace, is poured into the mold cavity. The choice of metal often depends on the desired properties of the final product, with common materials including aluminum, iron, and steel. The metal fills the mold, taking the shape of the pattern and solidifying as it cools.

Once the metal has completely cooled and solidified, the mold is broken apart to reveal the casting. This stage may require additional finishing processes, such as grinding or machining, to achieve the desired surface finish and dimensional accuracy.

The sand foundry process is not only cost-effective but also offers the flexibility to produce small and large batches of castings. Moreover, advancements in technology, such as computer-aided design (CAD) and 3D printing, have further enhanced the capabilities and efficiency of the sand foundry process, allowing for even more intricate designs and quicker turnaround times.

In summary, the sand foundry process remains a cornerstone of the metal casting industry, combining traditional techniques with modern innovations to meet the growing demands of manufacturing. Its adaptability and efficiency ensure that it remains a preferred method for producing a wide range of metal components across different sectors.

Post time:अक्ट . 30, 2024 11:12

Next:physical properties of foundry sand