The Importance of Resin Sand in Modern Foundry Applications

In the ever-evolving field of metal casting, resin sand has emerged as a pivotal material that enhances the quality and efficiency of foundry processes. As industries demand higher precision and better surface finishes in cast products, resin sand has become increasingly popular due to its unique characteristics.

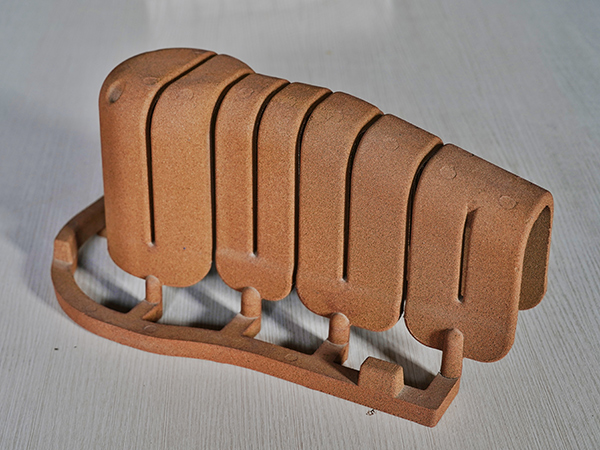

Resin sand is primarily composed of silica sand coated with a thermosetting resin, which is typically phenolic or furan-based. This combination gives the sand remarkable properties that set it apart from traditional green sand. One of the most significant advantages of resin sand is its ability to create highly detailed molds. The fine grain structure of the resin-coated sand adheres well during the mold-making process, allowing for intricate designs and complex shapes without compromising structural integrity.

Moreover, resin sand exhibits excellent dimensional stability. Unlike traditional sands that can suffer from moisture-related issues, resin sand maintains its shape and strength across varying temperatures. This feature is crucial in preventing defects such as warping and cracking during the casting process. As a result, manufacturers can achieve tighter tolerances, which is critical for industries that require high levels of precision, such as automotive and aerospace.

resin sand

Another noteworthy benefit of resin sand is its superior surface finish. The smoothness of the sand grains, coupled with the resin's binding properties, results in castings that require less machining and finishing. This not only reduces production time but also lowers the overall costs associated with post-casting processes. As industries strive for more sustainable practices, the efficiency of resin sand proves advantageous by minimizing waste and energy consumption.

However, the use of resin sand is not without its challenges. The curing process requires careful control of temperature and chemical reactions, which necessitates a well-equipped facility and skilled personnel. Furthermore, the environmental impact of the resins used in production must be managed effectively to meet regulatory standards and sustainability goals.

Overall, resin sand stands out as a crucial material in modern foundry applications. Its superior mold-making capabilities, dimensional stability, and enhanced surface finishes make it a favorite among manufacturers striving for excellence in their casting processes. As technology continues to advance, it is likely that the use of resin sand will expand further, driving innovations and improvements in manufacturing across various sectors. Embracing this material not only represents a step forward in efficiency but also aligns with the industry's ongoing quest for sustainability and quality.

Post time:सेप . 09, 2024 08:25

Next:レジンコーティングサンド製造プロセス - 高品質な鋳造材料