How Does Sand Casting Work?

Sand casting, a widely used method of metal casting, is appreciated for its versatility, simplicity, and cost-effectiveness. It is one of the oldest known casting processes, dating back thousands of years. This article will delve into the fundamentals of sand casting, including its process, materials, advantages, and applications.

The Sand Casting Process

The sand casting process involves several key steps

1. Pattern Creation The first step is to create a pattern that reflects the desired final product. Patterns can be made from various materials, such as wood, metal, or plastic, and are often slightly larger than the final casting due to shrinkage that occurs during cooling.

2. Mold Making Once the pattern is prepared, it is used to create a mold. In sand casting, the mold is formed by packing sand, often mixed with a binding agent (like clay) around the pattern. The sand is compacted to ensure it holds its shape when the pattern is removed.

3. Core Creation If the casting requires internal cavities or undercuts, cores made from sand are created. Cores are placed into the mold before casting to form these specific shapes.

4. Mold Assembly The mold halves, containing the pattern and cores (if used), are assembled together securely to prepare for pouring the molten metal.

5. Pouring Once the mold is ready, molten metal is carefully poured into it. The metal must be heated to its melting point, which varies depending on the type of metal being used, such as aluminum, steel, or iron.

6. Cooling After pouring, the metal is allowed to cool and solidify within the mold. The cooling time depends on the metal type, the thickness of the casting, and the ambient temperature.

7. Mold Removal Once the metal has cooled and solidified, the sand mold is broken away to reveal the newly cast object. This process may involve shaking or ramming the mold to dislodge it from the casting.

8. Cleaning and Finishing Finally, the cast part may require cleaning to remove any residual sand and excess material. Additional finishing processes, including machining to achieve precise dimensions, are often necessary before the part is ready for use.

Materials Used in Sand Casting

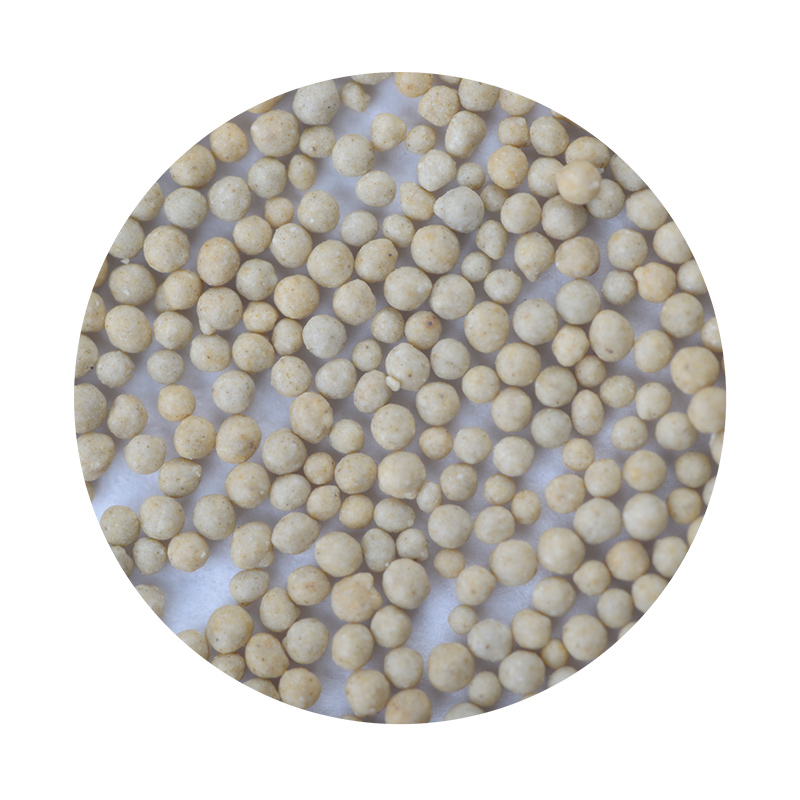

how does sand casting work

The primary material used in sand casting is silica sand, which provides excellent mold strength and thermal stability. To enhance its properties, binders such as clay or resin are mixed with the sand. The choice of metal also plays a crucial role; common metals include cast iron, steel, aluminum, and bronze, each selected based on the required mechanical properties and application of the final product.

Advantages of Sand Casting

Sand casting offers several advantages

- Cost-Effectiveness The materials used in sand casting are relatively inexpensive, and the process can be set up quickly without the need for extensive machinery. - Versatility This method can accommodate complex shapes and large items, making it suitable for a wide range of applications, from small components to large machinery parts.

- Easy Modification Changes can be made to patterns or molds relatively easily, allowing for rapid prototyping and iteration.

- Wide Range of Materials Sand casting can work with various metals and alloys, offering manufacturers flexibility in material choice.

Applications of Sand Casting

Sand casting is utilized across various industries due to its adaptability and efficiency. Common applications include

- Automotive Parts Many engine blocks, transmission cases, and other vital automotive components are produced using sand casting, benefiting from its ability to create complex shapes and robust structures. - Aerospace Components Sand casting is often employed in producing parts for aircraft and spacecraft due to its capacity to work with lightweight metals like aluminum.

- Artistic Pieces Beyond industrial applications, sand casting is also used in producing sculptures and decorative items, showcasing the aesthetic potential of this method.

Conclusion

In summary, sand casting is a fundamental manufacturing process that continues to play an essential role in various industries today. With its straightforward methodology, cost-effectiveness, and versatility, sand casting remains a preferred technique for producing metal components and will likely continue to evolve with advancements in materials and technology. Understanding how this process works provides insight into the craftsmanship and engineering behind the countless products we use every day.

Post time:नोभ . 08, 2024 00:24

Next:Exploring the Riches of Gold Sandy Landscapes and Their Hidden Treasures