Exploring the Wonders of Ceramic Sand

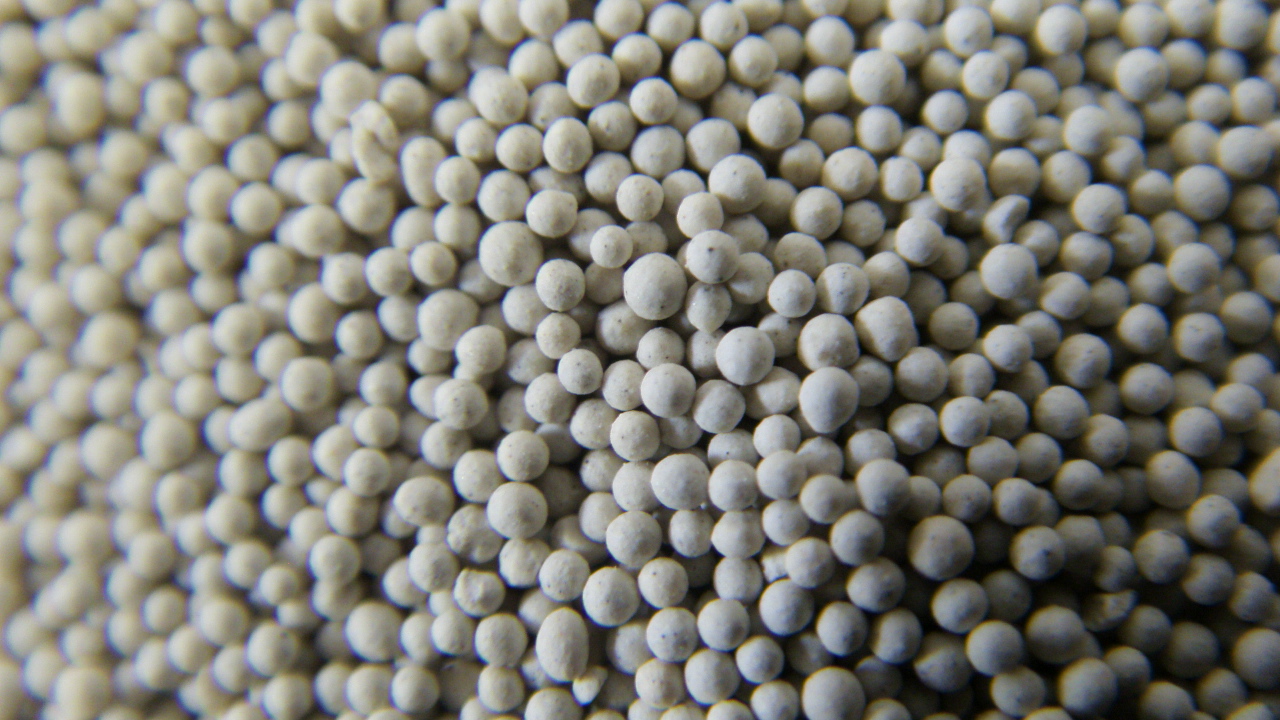

Ceramic sand, a versatile and innovative material, has been gaining significant attention in various industries due to its unique properties and applications. Often utilized in the manufacturing of ceramics, glass, and even in construction, ceramic sand is a high-performance material that offers various benefits over traditional sand types.

Ceramic sand is produced from natural raw materials, which are processed and formed into fine granules with a unique structure. This processing enhances its performance traits such as strength, thermal resistance, and chemical stability. Unlike conventional sand, which can be subject to erosion and degradation, ceramic sand maintains its integrity under a wide range of environmental conditions. This durability makes it an ideal choice for applications in demanding environments, such as foundries, where it is used as a mold material for metal casting.

One of the most significant advantages of ceramic sand is its thermal properties

. It can withstand extremely high temperatures without losing its structural integrity, making it a favored material in the manufacturing of refractory products. These products are essential in industries that require materials capable of withstanding thermal shock, such as steel, glass, and cement production. The high melting point of ceramic sand ensures that it remains stable and functional even under intense heat, thus enhancing the efficiency and safety of industrial processes.ceramic sand

Moreover, ceramic sand is extremely effective in filtering applications. Its fine granules and specific shape provide an increased surface area for trapping impurities and particulates. This has led to its adoption in water treatment facilities, where it is utilized in filtration systems to improve water quality. The material's non-toxic nature further amplifies its appeal in environmental applications, where maintaining purity and safety is paramount.

In the realm of construction, ceramic sand is being explored as an eco-friendly alternative to traditional aggregates. With the construction industry increasingly attentive to sustainability, the use of ceramic sand can contribute to reducing the ecological footprint of construction activities. Its lightweight nature facilitates easier handling and transportation, while still providing structural strength and stability. For example, when used in concrete mixes, ceramic sand can help to reduce the overall weight of the structure without sacrificing load-bearing capabilities.

Furthermore, ceramic sand has potential in the realm of 3D printing technology. With the rise of additive manufacturing, the demand for versatile and reliable materials has increased. Ceramic sand's unique properties could be harnessed in 3D printing to create complex geometries and designs that are both functional and aesthetically pleasing. Its capability to be molded easily allows for innovation in product design, opening up new avenues in art, architecture, and industrial applications.

In conclusion, ceramic sand stands out as a multifunctional material with an array of applications across diverse industries. From enhancing the efficiency of manufacturing processes to contributing to sustainable construction practices, its unique properties make it an invaluable asset in modern technological advancements. As research continues to unveil further potential uses, ceramic sand is poised to become an integral component in shaping the future of materials science.

Post time:नोभ . 01, 2024 21:42

Next:zand gieten