Revolutionizing Manufacturing The Untapped Potential of Wet Sand 3D Printing

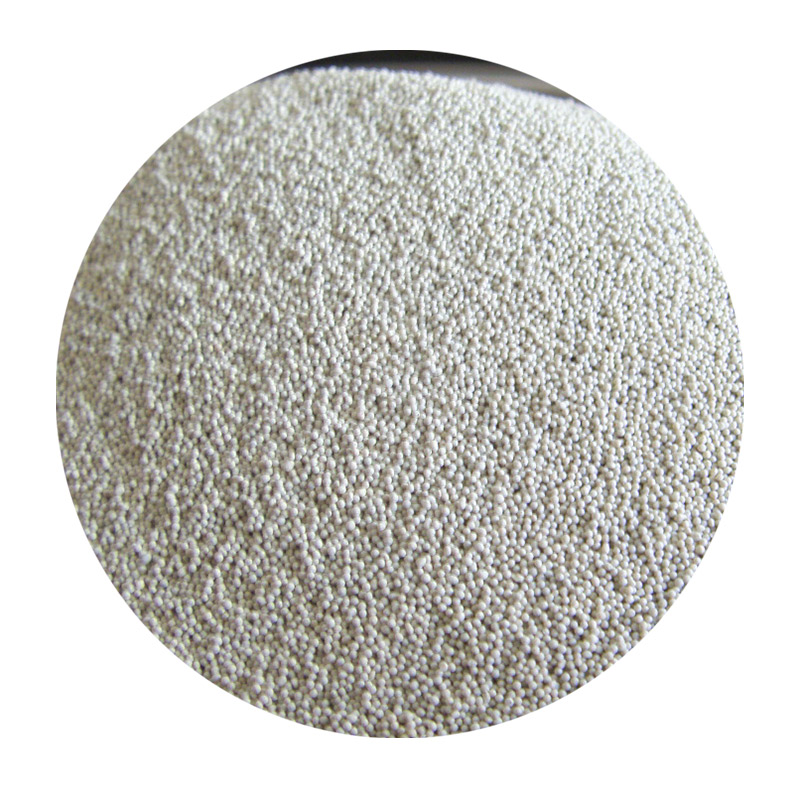

The landscape of 3D printing has been dramatically transformed by innovations that once seemed unimaginable. Among these advancements, wet sand 3D printing has emerged as a pioneering technique, challenging the conventions of traditional manufacturing while offering sustainable, cost-effective, and high-quality results. For manufacturers, designers, and engineers seeking to leverage cutting-edge technologies, understanding wet sand 3D printing's unique potential is indispensable. In essence, wet sand 3D printing utilizes a binding agent blended with sand to construct precise molds or parts from digital designs. Unlike its dry counterpart, wet sand 3D printing incorporates moisture, creating a stronger bond between particles. This slight adjustment plays a crucial role in enhancing the mechanical properties and durability of the final product, minimizing breakage during or after the manufacturing process.

One of the foremost advantages of wet sand 3D printing is its environmental sustainability. Traditional 3D printing often relies on synthetic materials like plastics, which contribute to environmental degradation. Wet sand, a naturally abundant material, reduces reliance on plastics, thereby decreasing harmful emissions and waste. Moreover, sand is reusable, allowing for a circular manufacturing process that aligns with global sustainability goals.

The precision this technique offers is equally noteworthy. Wet sand 3D printing empowers creators to manufacture complex geometries that were previously impossible or economically impractical with traditional methods. Complex internal structures, intricate surface details, and durable molds are all within reach, providing unprecedented freedom for creativity and innovation in product design. For industries, this translates to a broader range of design possibilities and enhanced production capabilities, from automotives to aerospace engineering.wet sand 3d print

From a cost perspective, wet sand 3D printing presents substantial economic benefits. The raw material, sand, is relatively inexpensive and widely available. Combined with the reduced labor costs due to automation, companies can achieve a higher return on investment over time. This makes wet sand 3D printing highly attractive for startups and SMEs aiming to enter competitive markets without incurring overwhelming expenses on material and manpower.

Authenticity and reliability are paramount in advancing new technologies. The adoption of wet sand 3D printing is underpinned by rigorous research and field-testing to ensure it meets industry standards. Successful case studies have demonstrated its applicability and efficiency, reinforcing confidence in its potential. Collaborations between academic institutions and leading manufacturers have underscored its scalability, setting a benchmark for future innovations.

Despite its proven benefits, wet sand 3D printing's potential remains largely untapped. This calls for increased awareness and knowledge transfer within the industry. By encouraging knowledge sharing through workshops, webinars, and industry conferences, stakeholders can witness firsthand the advantages and applications of this transformative technology.

In conclusion, wet sand 3D printing is not merely a trend; it is a revolution in the manufacturing sector. Its commitment to environmental sustainability, cost-effectiveness, and design flexibility establishes it as a frontrunner in the future of manufacturing. Organizations that invest in this technology today are poised to lead the charge in innovation, setting themselves apart in an increasingly competitive landscape. As the industry continues to evolve, wet sand 3D printing will undoubtedly play a pivotal role in shaping the products of tomorrow.

Next:sanding 3d prints