The Importance of Sand Casting Foundries

Sand casting is one of the oldest and most versatile manufacturing processes, widely utilized in the foundry industry for producing metal components. Sand casting foundries play a crucial role in various sectors, including automotive, aerospace, and machinery manufacturing. The process involves creating a mold from sand and then pouring molten metal into it to form intricate shapes and designs.

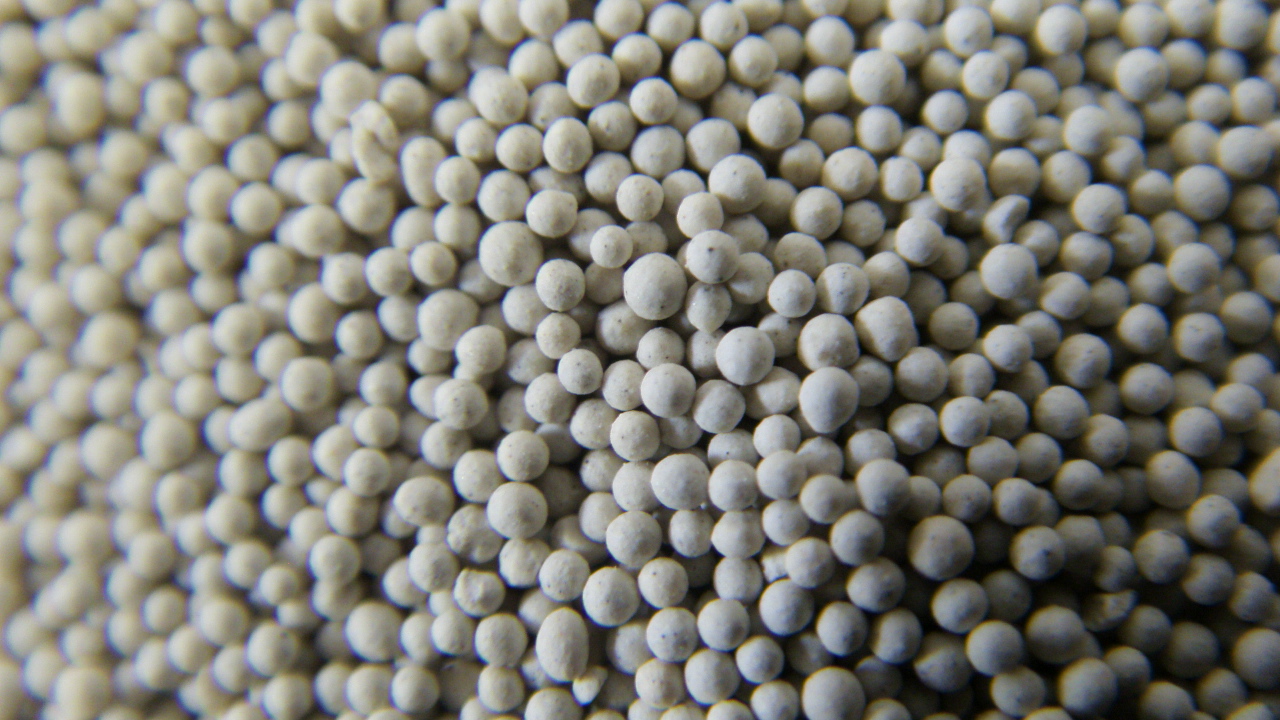

The primary material used in sand casting is silica sand, which possesses excellent properties for mold-making. The grains of sand are mixed with a binding agent, typically clay, and water to create a mold that can withstand the pressure of molten metal. This method allows for the production of complex geometries and large-scale components that would be challenging to achieve through other manufacturing techniques.

One of the standout features of sand casting foundries is their adaptability to different metals. They can work with various materials, including aluminum, brass, bronze, and iron, making them suitable for a wide range of applications. Additionally, the process can accommodate both small batch productions and large-scale manufacturing, making it ideal for customized projects as well as mass production.

sand casting foundries

The benefits of sand casting extend beyond flexibility in design and metal choice. It is also a cost-effective process, particularly for low to medium production runs. The materials required for sand molds are relatively inexpensive, and the process itself allows for quick turnaround times. This efficiency is further enhanced by modern technologies, such as computer-aided design (CAD) and automated molding equipment, which streamline production and improve precision.

Moreover, sand casting foundries contribute significantly to sustainability in manufacturing. Many foundries implement recycling practices to reuse sand and reduce waste. This commitment to environmental responsibility helps to minimize the ecological footprint of metal casting operations.

In conclusion, sand casting foundries are integral to the manufacturing landscape, offering flexibility, cost-effectiveness, and sustainability. With their ability to produce intricate designs in various metals, they continue to meet the demands of diverse industries while embracing modern technologies. As the manufacturing sector evolves, sand casting will undoubtedly remain a vital process, shaping the future of industrial production. The significance of these foundries will only grow, making them a cornerstone of innovation and efficiency in metalworking.

Post time:ऑक्टोबर . 06, 2024 20:17

Next:coated sand casting