Recognizing the value that these discs offer, countless workshops and DIY enthusiasts have switched their abrasive supplies to ceramic options. Professional entities have standardised the use of ceramic sanding discs for critical operations, appreciating the cost-effectiveness brought through their prolonged lifecycle and reduced replacement frequency. Testimonials from industry professionals frequently highlight not just the financial savings, but also the improvements in workflow efficiency and end-product quality. Trust in the product further stems from the rigorous testing and development ceramic sanding discs undergo. Leading manufacturers invest significantly in research to enhance the performance characteristics of ceramics, ensuring that they stand up to real-world demands. Such commitment to quality control fosters consumer confidence, knowing that their tools meet the highest standards of craftsmanship and durability. For those considering a switch to ceramic sanding discs, expertise is abundant online through forums and professional networks. These platforms offer real-world insights and tips from seasoned users, further validating the discs' advantages and applications in diverse scenarios. Whether sanding expansive surfaces or working on intricate details, recommendations from fellow users can assist new adopters in optimising their techniques and getting the most out of their ceramic sanding tools. In summation, ceramic sanding discs represent an outstanding blend of innovative engineering and professional-grade performance. For experts committed to delivering supreme quality in metal and woodwork, these discs are not just an accessory but a pivotal component of their toolkit. By investing in ceramic technology, users endorse a method refined through expertise and trusted for its unparalleled outcomes. Post time:जानेवारी . 09, 2025 11:53

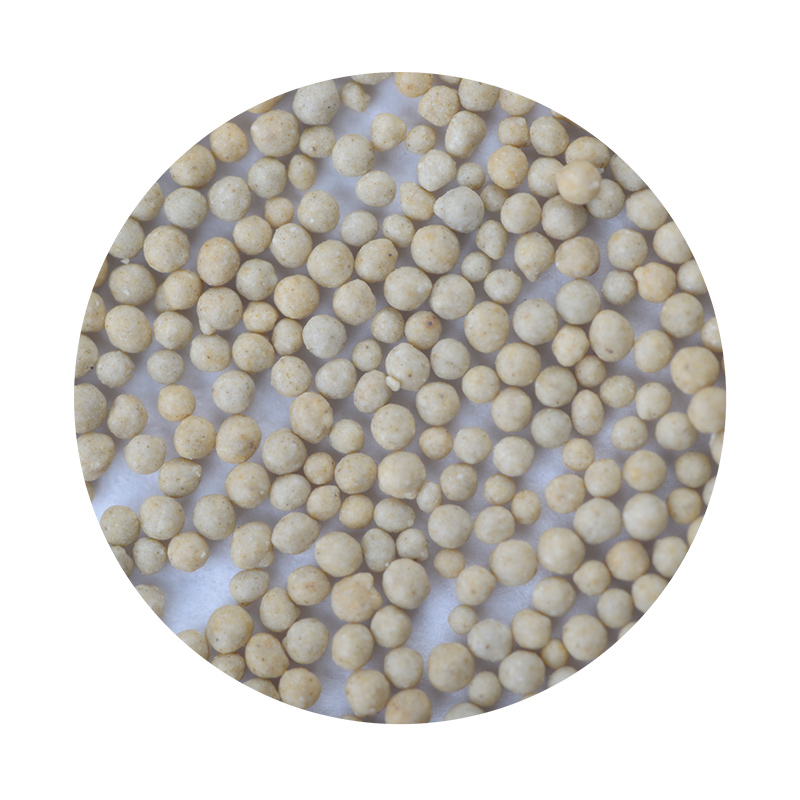

Next:Sintered ceramic sand made in China same with Cerabeads AFS 60