How to Make Foundry Sand

Foundry sand is a crucial component in metal casting, playing a vital role in producing high-quality metal parts. It is designed to withstand the high temperatures of molten metal, provide a good surface finish, and enable easy removal of the cast. Here’s a brief guide on how to make foundry sand effectively.

Step 1 Choose the Right Sand

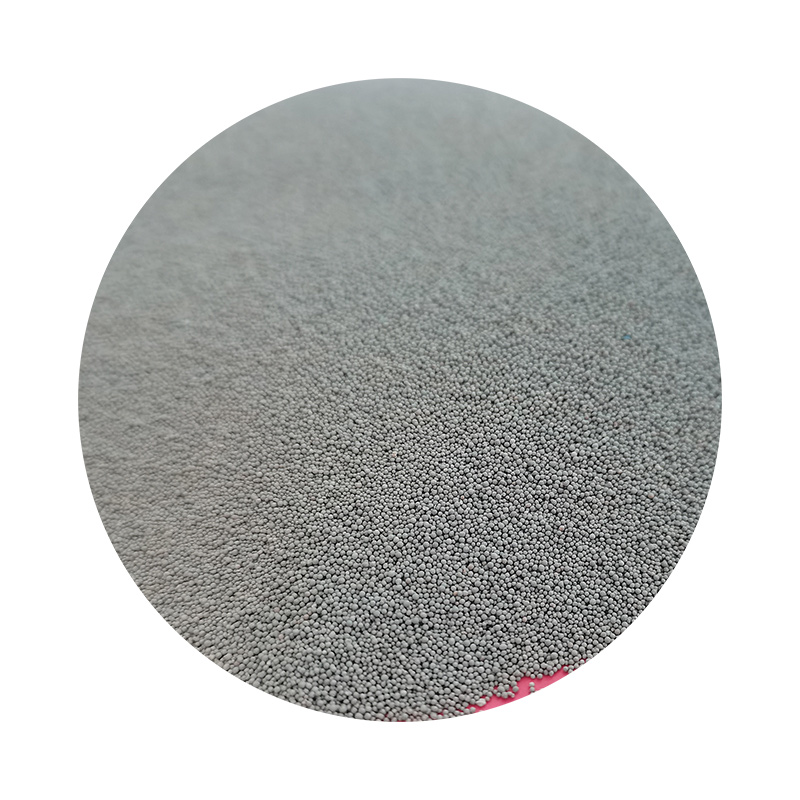

The foundation of good foundry sand is the type of sand used. The best choice is silica sand due to its high melting point and resistance to thermal shock. Look for clean, fine-grained silica sand that has a uniform particle size. Avoid sands with clay or impurities, as these can negatively impact the quality of the cast.

Step 2 Prepare the Sand

Once you have selected your silica sand, it’s essential to prepare it for use. The sand may need to be washed to remove any contaminants or fine particles that could affect its performance. A simple rinse with water followed by drying in the sun or using a drying oven can help achieve the desired cleanliness and moisture level.

Step 3 Add Binders

how to make foundry sand

To improve the properties of the sand, binders are often added. The most common binders used in foundry sand are clay and resin. Bentonite clay is frequently used due to its excellent binding qualities and compatibility with sand. A typical mixture comprises about 5-10% bentonite clay mixed with the sand. Alternatively, a resin-bonded system can be used, where liquid resin is mixed with sand and then hardened using heat or a chemical catalyst.

Step 4 Moisture Control

Controlling the moisture content in foundry sand is crucial. The optimal moisture content usually ranges from 2-5%. Too much moisture can lead to steam explosions, while too little can hinder the binding properties. Achieving the right balance involves careful monitoring and sometimes artificial drying methods.

Step 5 Testing the Sand

Before using foundry sand for casting, testing is imperative to ensure it meets the necessary standards. Common tests include the shakeout test, which determines how easily the sand can be re-used after casting, and the permeability test, which assesses how well gases can escape during the casting process.

Conclusion

Making foundry sand requires careful selection of materials, proper preparation, and attention to detail in moisture control and testing. When done correctly, it results in high-quality castings with excellent surface finishes. By following these steps, you can create effective foundry sand tailored for various metal casting applications, ensuring efficiency and quality in your foundry operations. Properly prepared and tested foundry sand can significantly enhance the overall casting process, leading to improved productivity and product quality.

Post time:9-р сар . 24, 2024 11:58

Next:Examples of Products Made Using Sand Casting Techniques and Methods