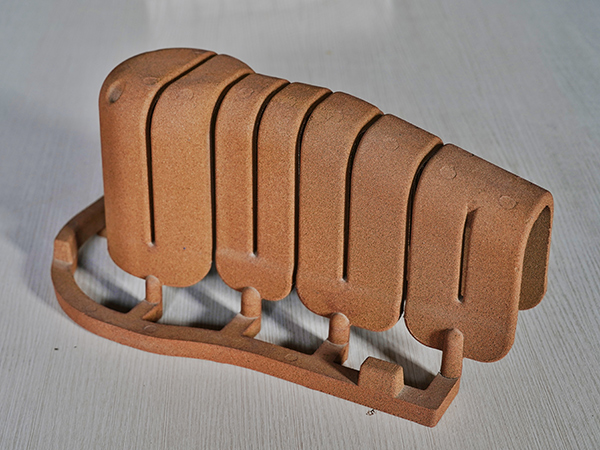

Shell Molding Casting is a process oriented towards precision and efficiency. By coating a heated metal pattern with resin-bonded sand, a thin but strong shell mold is formed. Not only does this process support complex designs, but it also ensures tight tolerances and fine finishes. Shell molding is less labor-intensive and offers rapid production rates, making it a popular choice for high-volume manufacturing runs. However, the investment in patterns and longer setup times should be taken into account, especially for low-volume projects. Investment in the No-Bake Sand Casting process can significantly enhance production capabilities. This advanced method uses chemically bonded sand, curing at room temperature. No-bake sand casting provides unmatched dimensional accuracy and surface finishes. Although slower in production than other methods, its ability to produce large, high-quality castings justifies its place in industries where precision is non-negotiable. Finally, the latest technological advancement is Additive Manufacturing Integrated Sand Casting. Also known as 3D printing-based sand casting, this innovative approach involves the use of 3D printing technology to create sand molds. This process offers unrivaled flexibility in design, enabling intricate patterns and complex geometries not feasible with traditional sand casting methods. While still emerging, this technology promises a new era in sand casting, minimizing material waste and customization turnaround times. Sand casting's diversity in methodology allows it to remain a cornerstone process across industrial sectors. Choosing the right type of sand casting process depends on the project’s needs, balancing cost, detail, strength, and production speed. While each method has its unique set of advantages, they are all bound by the fundamental principles of ensuring high-quality outcomes in manufacturing. Through a well-informed selection of any of the sand casting processes mentioned, industries can optimize their manufacturing operations, ensuring products not only meet but exceed regulatory standards and consumer expectations. This understanding not only enhances operational efficiency but also reinforces trust and reliability in the quality of products delivered to the market. Post time:ഫെബ്രു . 13, 2025 11:16

Next:types of sand casting