Achieving Smooth 3D Prints Without Sanding Techniques and Tips

3D printing has revolutionized the way we create objects, enabling makers to bring their digital designs to life with incredible speed and precision. However, achieving a smooth finish on 3D prints has often been a challenge due to the inherent layer-by-layer nature of the process. Many hobbyists and professionals alike find themselves facing the tedious task of sanding their prints to achieve the desired smoothness. Fortunately, there are several techniques that can help you attain a smoother finish straight from the printer, eliminating or significantly reducing the need for sanding.

1. Optimal Printer Settings

One of the most effective ways to achieve smoother prints is by adjusting the settings on your 3D printer. The layer height plays a crucial role in the finish quality of your print. Lowering the layer height will result in finer layers, which can significantly reduce the appearance of layer lines. While this may increase the print time, the smoother finish can save you time in post-processing.

Additionally, tweaking the print speed can also make a difference. Slower printing speeds can allow for better extrusion and adhesion between layers, resulting in a more uniform surface finish. Experimenting with different settings based on the material you are using can lead to optimal results.

2. Use of High-Quality Filament

The choice of filament impacts the surface quality of your final product. Investing in high-quality filaments, such as PLA, ABS, or PETG, can produce smoother prints compared to lower-quality alternatives. Many manufacturers offer specialized filaments designed for better surface finishes, and these can often be worth the extra cost for their improved results.

Filaments with additives, such as those containing nylon or specialty blends, can also help minimize layer visibility

. Researching and selecting the right filament for your project can make a significant difference in achieving a smooth print without the need for extensive sanding.3. Advanced Slicing Techniques

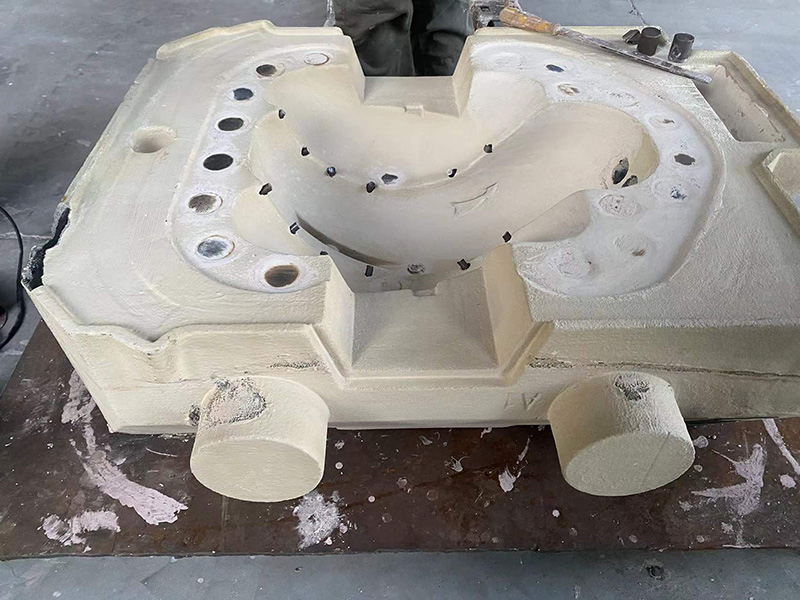

smooth 3d prints without sanding

Using advanced slicing software can provide you with greater control over print settings and allow for optimization tailored to specific models. Features like adaptive layer height can help in automatically adjusting layer thickness based on the geometry of the print, leaving smoother surfaces on large flat areas while maintaining detail in other regions.

Moreover, ensuring that your print orientation is considered can also lead to smoother finishes. For example, positioning the print in such a way that minimizes the number of visible layers can be beneficial. Prioritizing the orientation to where the least visible surfaces are facing upwards can drastically reduce the appearance of imperfections.

4. Temperature Management

Temperature plays an essential role in print quality and finish. Ensuring the nozzle temperature is set correctly can help achieve better flow and adhesion of the filament. If the temperature is too low, the filament may not extrude smoothly, leading to rough surfaces. On the other hand, if it’s too high, it can result in oozing and stringing. Finding the sweet spot through testing can lead directly to a smoother output.

Moreover, using an enclosure for your printer can help maintain a stable ambient temperature, reducing warping and improving layer adhesion for a more polished finish.

5. Chemical Smoothing Techniques

For those who seek a near-glass-like finish, chemical smoothing methods can be highly effective. This technique typically involves exposing prints to specific solvents that dissolve the surface of the filament, creating a smooth finish. For example, ABS prints can be smoothed with acetone vapor, while PLA can be treated with ethyl acetate or other suitable solvents. However, it’s essential to handle these chemicals with care and in a well-ventilated area.

Conclusion

Achieving smooth 3D prints without sanding is not only possible but also attainable with the right techniques and knowledge. By optimizing your printer settings, choosing high-quality filaments, utilizing advanced slicing software, managing temperatures, and exploring chemical smoothing methods, you can significantly enhance the finish of your 3D prints. Embracing these strategies will not only save you valuable time but also elevate the quality of your creations, allowing you to focus more on your designs and less on post-processing tasks. Happy printing!

Post time:ഒക്ട് . 21, 2024 21:05

Next:super sand g2