Sand Casting Service A Comprehensive Guide to the Process and Its Benefits

Sand casting is a renowned metal casting process that has been utilized for centuries. It is a versatile technique that allows for the production of complex shapes and a wide variety of materials, making it one of the most popular methods in foundries around the world. This article will explore the intricacies of sand casting service, its benefits, and what industries commonly rely on this approach.

What is Sand Casting?

At its core, sand casting involves creating a mold from sand to shape molten metal into a desired form. The process begins with the production of a pattern, usually made from metal, plastic, or wood, that mirrors the item to be cast. This pattern is placed into a sand mixture, which is tightly packed around it to form a mold. Once the mold is prepared, it is opened, the pattern is removed, and molten metal can be poured into the cavity left behind. After the metal cools and solidifies, the mold is broken apart to reveal the finished cast object.

The Sand Casting Process

The process of sand casting can be broken down into several key steps

1. Pattern Making A precise model of the desired object is created. This pattern needs to compensate for shrinkage and ensure accuracy in the final cast item.

2. Mold Preparation A mixture of sand, clay, and water is packed around the pattern in a mold box. The sand must be compact enough to retain its shape but also allow easy removal of the final product.

3. Pouring the Metal After the mold is created, it is preheated if necessary, and molten metal is carefully poured into the mold cavity.

4. Cooling The metal is allowed to cool and harden. Cooling time can vary based on the type of metal used and the thickness of the casting.

5. Mold Removal Once the metal has cooled sufficiently, the sand mold is removed to reveal the finished part.

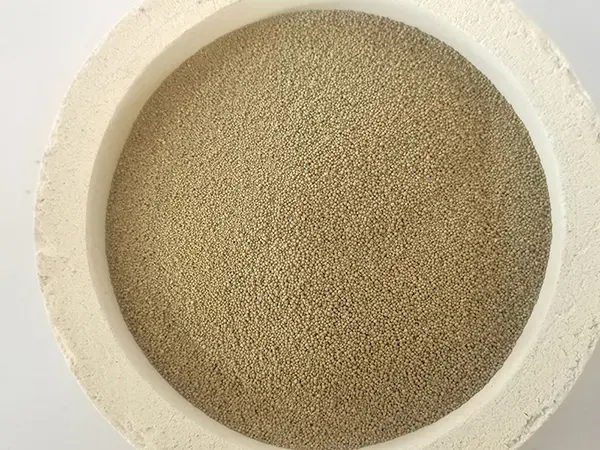

sand casting service

Benefits of Sand Casting

Sand casting offers several benefits that make it an attractive option for various applications

1. Versatility Sand casting is suitable for producing parts from a wide range of materials, including aluminum, iron, steel, and bronze. This allows manufacturers to choose the best material for their specific needs.

2. Cost-Effectiveness The availability of sand as a primary material and the simplicity of the sand casting process make it a cost-effective production method, particularly for low to medium production volumes.

3. Complex Shapes The process allows for intricate designs and complex geometries that may be difficult to achieve with other manufacturing techniques.

4. Large Part Capability Sand casting can produce large parts, catering to industries such as automotive, aerospace, and heavy machinery.

5. Prototype Development Rapid prototyping is feasible with sand casting, as patterns can be created quickly and modifications can be easily integrated.

Industries That Utilize Sand Casting

Several industries heavily depend on sand casting services, including

- Automotive Industry For manufacturing engine blocks, cylinder heads, and various other components. - Aerospace Used in the production of critical structural components where precision is essential. - Construction Fabrication of hardware and architectural components. - Energy Sector Components for turbines, pumps, and machinery.

Conclusion

Sand casting service is a time-honored technique that remains vital in various sectors. Its unique ability to produce complex shapes, coupled with cost-effectiveness, has ensured its continued relevance in modern manufacturing. Whether for prototypes or large-scale production, sand casting remains a critical component of the industrial landscape, helping to bring innovative designs to life.

Post time:നവം . 07, 2024 17:18

Next:Applications and Advantages of Sand Casting in Manufacturing Processes