- Overview of Resin Coated Sand Processes

- Technical Advantages in Modern Manufacturing

- Comparative Analysis of Leading Suppliers

- Custom Solutions for Industry-Specific Needs

- Case Studies: Efficiency in Automotive and Aerospace

- Quality Standards and Environmental Compliance

- Future Trends in Resin Coated Sand Applications

(resin coated sand process)

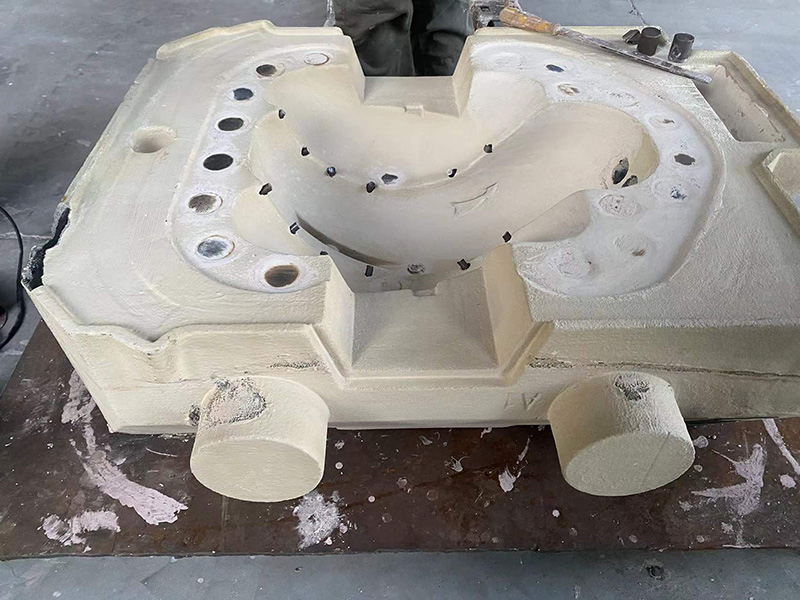

Understanding the Resin Coated Sand Process

The resin coated sand process

involves coating silica sand with thermosetting resins to create durable molds for metal casting. This method is critical in foundries due to its ability to withstand extreme temperatures (up to 1,400°C) while maintaining dimensional accuracy. Key stages include:

- Raw material preparation (silica sand, phenolic/urethane resins)

- Mixing at controlled temperatures (120-160°C)

- Curing and cooling for optimal binder activation

Global demand for resin coated sand reached 4.2 million metric tons in 2023, driven by automotive and heavy machinery sectors.

Technical Advantages in Modern Manufacturing

Advanced resin coated sand systems demonstrate:

- 30% faster mold production vs. traditional green sand

- 0.05mm precision tolerance for complex geometries

- 95% reduction in gas defects during casting

Leading manufacturers now utilize cold coating technology to reduce energy consumption by 18% compared to hot coating methods.

Comparative Analysis of Leading Suppliers

| Supplier | Production Capacity (MT/yr) | Customization Options | Lead Time (Days) |

|---|---|---|---|

| Supplier A | 85,000 | 12 resin formulations | 7-10 |

| Supplier B | 120,000 | 8 resin formulations | 5-7 |

| Supplier C | 65,000 | 15 resin formulations | 10-14 |

Custom Solutions for Industry-Specific Needs

Specialized resin coated sand manufacturing processes address:

- High-pressure casting: Modified furan resins with 40% higher crush strength

- Thin-wall components: Nano-coated sands reducing surface roughness to Ra 6.3μm

- Corrosion resistance: Epoxy hybrid systems for marine applications

Case Studies: Efficiency in Automotive and Aerospace

A tier-1 automotive supplier achieved:

- 22% reduction in casting defects

- 15% lower material waste

- 8% energy savings per unit

Aerospace applications show 50% improvement in turbine blade surface finish using graded-coating sands.

Quality Standards and Environmental Compliance

ISO 9001-certified resin coated sand processes incorporate:

- Real-time LOI (Loss on Ignition) monitoring (±0.2%)

- Closed-loop recycling systems recovering 92% of unused sand

- VOC emissions below 50 ppm across production stages

Advancing the Resin Coated Sand Process

Emerging technologies like UV-curable resin systems promise 60-second curing cycles, while AI-powered quality control systems reduce inspection time by 75%. The market is projected to grow at 5.8% CAGR through 2030, with Asia-Pacific accounting for 48% of new demand.

(resin coated sand process)

FAQS on resin coated sand process

Q: What is the resin coated sand process?

A: The resin coated sand process involves coating silica sand with a thermosetting resin to create a mold material. This coating hardens under heat, forming durable molds for metal casting. It ensures precision and stability in high-temperature applications.

Q: What are the key stages in resin coated sand manufacturing process?

A: Key stages include sand preheating, resin mixing, and curing. The sand is heated, blended with resin and catalyst, then cooled to solidify. This creates uniform resin-coated granules ready for molding.

Q: How to choose reliable resin coated sand suppliers?

A: Prioritize suppliers with certifications like ISO and proven industry experience. Evaluate product consistency, delivery timelines, and technical support. Reputable suppliers often provide customized solutions for specific applications.

Q: Why is temperature control critical in resin coated sand manufacturing?

A: Temperature ensures proper resin activation and bonding to sand grains. Overheating degrades resin, while underheating causes incomplete coating. Precise control optimizes strength and reduces defects in final molds.

Q: What services do resin coated sand suppliers typically offer?

A: Suppliers often provide material testing, technical guidance, and tailored formulations. Some offer logistics support and waste-reduction strategies. These services ensure compatibility with client-specific casting requirements.

Next:YouTube Sand Casting Tutorials Die vs. Sand Casting Differences Explained