The Role and Importance of Coated Sand in Modern Applications

Coated sand has emerged as a crucial material in various industries, particularly in casting, construction, and the production of high-performance materials. This innovative solution involves the application of a coating substance to sand grains, enhancing their properties and making them more suitable for specific uses. The versatility and effectiveness of coated sand have made it a popular choice in numerous applications.

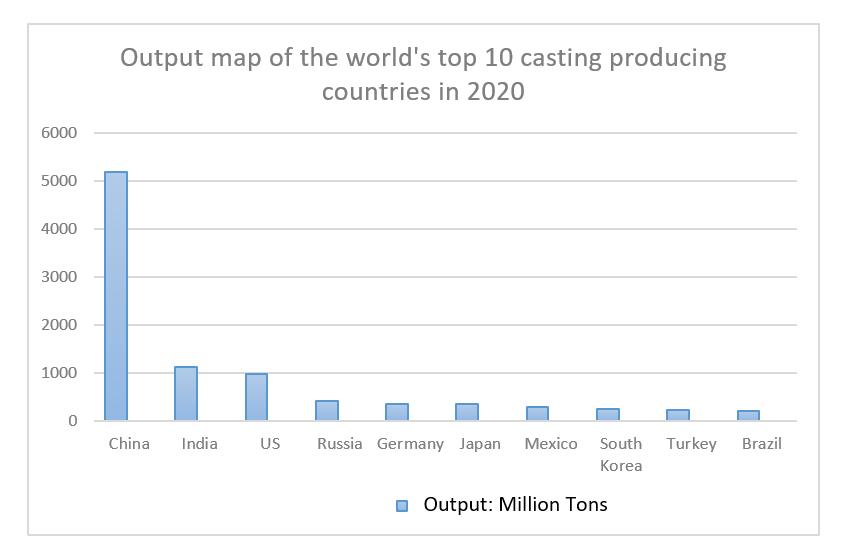

One of the primary uses of coated sand is in the foundry industry, where it serves as a crucial component in the casting process. In sand casting, the quality of the sand mixture significantly influences the final product's properties. By coating the sand particles with binders and other additives, manufacturers can improve the strength, surface finish, and dimensional accuracy of the castings. This is particularly important for the production of intricate designs and components that require high precision. The enhanced binding properties of coated sand lead to reduced defects and a more efficient production process.

Additionally, coated sand plays a vital role in the oil and gas industry, particularly in hydraulic fracturing or fracking

. In this context, coated sand is used as a proppant to keep fractures open in hydrocarbon reservoirs. The coating typically consists of resin or other adhesives, which enhance the sand's strength and help it withstand the immense pressures encountered underground. This application significantly boosts the recovery of oil and gas, making it a valuable resource in energy production.coated sand

Moreover, coated sand has found its way into the realm of construction materials. Its use in concrete and as a lightweight fill material has garnered attention due to its ability to improve the mechanical properties of the final product. For example, incorporating coated sand into concrete mixtures can enhance workability, reduce water demand, and ultimately lead to stronger and more durable structures. This application is especially beneficial in regions prone to extreme weather conditions, where building resilience is of utmost importance.

The environmental impact of coated sand is also worth noting. As industries become increasingly conscious of sustainability, the use of recycled or eco-friendly coating materials presents an opportunity to reduce waste and lower the carbon footprint of manufacturing processes. Innovations in coated sand technology continue to evolve, with research focusing on developing biodegradable coatings that minimize environmental harm while maintaining performance standards.

In conclusion, coated sand has established itself as a vital material across various sectors, particularly in foundry applications, oil and gas extraction, and construction. Its ability to enhance the performance of sand in casting processes, support energy production, and improve construction material properties underscores its importance in modern industrial practices. Continued advancements in coated sand technology may open new avenues for sustainable and efficient solutions in an ever-evolving landscape. As industries strive for improved quality and sustainability, coated sand is poised to play an essential role in shaping the future.

Post time:സെപ് . 18, 2024 21:24

Next:Tecnologia de fundição em areia