Understanding Ceramic Sand Properties, Applications, and Future Prospects

Ceramic sand, also known as high-performance sand or ceramic proppant, has emerged as a revolutionary material in various industries due to its unique properties and versatile applications. Unlike traditional sand, ceramic sand is engineered from advanced materials, offering superior strength, durability, and thermal resistance. This article explores the characteristics, uses, and future implications of ceramic sand in various sectors.

Properties of Ceramic Sand

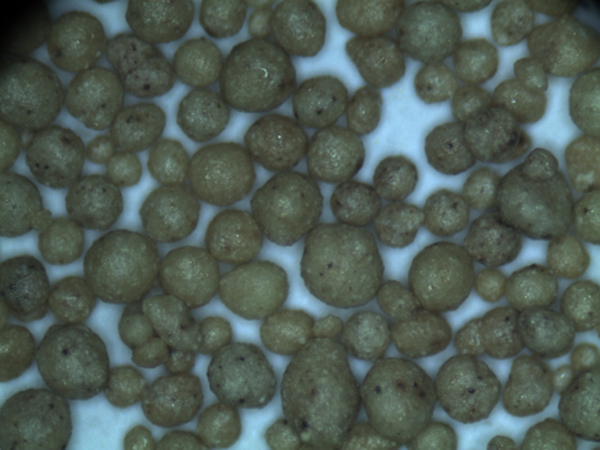

Ceramic sand is typically made from kaolin, a type of clay mineral that undergoes a series of processes, including grinding, shaping, and firing at high temperatures. This process transforms the clay into a hard, dense material with a range of beneficial properties. One of the standout features of ceramic sand is its high compressive strength, which can withstand substantial loads without deforming or breaking. This property makes it particularly valuable in applications where traditional sand would fail, such as in hydraulic fracturing for oil and gas extraction.

Furthermore, ceramic sand exhibits excellent thermal resistance, enabling it to function effectively in high-temperature environments. Its low thermal conductivity allows it to maintain temperature stability, making it suitable for various industrial processes. Additionally, ceramic sand's uniform particle size distribution contributes to its efficient flow characteristics, essential for precision applications in manufacturing and construction.

Applications of Ceramic Sand

The applications of ceramic sand are diverse, covering a range of industries from oil and gas to construction and foundry operations

.ceramic sand

1. Oil and Gas Industry One of the most prominent uses of ceramic sand is in hydraulic fracturing, also known as fracking. In this process, ceramic sand acts as a proppant, keeping fractures open and allowing oil and gas to flow more freely from the reservoir. Compared to traditional proppants like silica sand, ceramic sand offers superior strength and conductivity, enhancing the overall efficiency of the extraction process.

2. Foundry Industry In foundries, ceramic sand is utilized for producing precision metal castings. Its high-temperature resistance and ability to maintain shape under heat make it an ideal material for molding processes. It also contributes to producing smoother surface finishes and intricate designs, which are paramount in high-quality castings.

3. Construction Industry Ceramic sand is increasingly being recognized for its advantages in construction applications. Its lightweight nature and high strength make it suitable for lightweight concrete, improving the structural integrity of buildings while reducing overall weight. Additionally, its thermal properties support energy-efficient construction practices, as structures built with ceramic sand can better regulate indoor temperatures.

4. Environmental Applications Another promising application of ceramic sand lies in environmental remediation. Due to its porous nature, it can be used in filtration systems to treat wastewater or in soil amendments to improve drainage and reduce compaction in agricultural settings.

Future Prospects

As industries seek more sustainable and efficient materials, the demand for ceramic sand is expected to grow. Research and development efforts are focusing on enhancing the properties of ceramic sand further, investigating new formulations and production techniques to create even stronger and more versatile products. Additionally, advancements in recycling methods could allow for the reuse of spent ceramics, minimizing waste and supporting a circular economy.

In conclusion, ceramic sand represents a significant advancement over traditional sand, offering a range of properties that enhance its performance in various applications. As industries continue to innovate and demand higher-performing materials, ceramic sand is poised to play a crucial role in shaping the future of many sectors. With ongoing research and development, the potential applications and benefits of ceramic sand could expand even further, leading to more sustainable practices and improved efficiencies across multiple industries.

Post time:ഡിസം . 07, 2024 12:26

Next:resin coated sand