Why Sand Casting is Preferred in Manufacturing

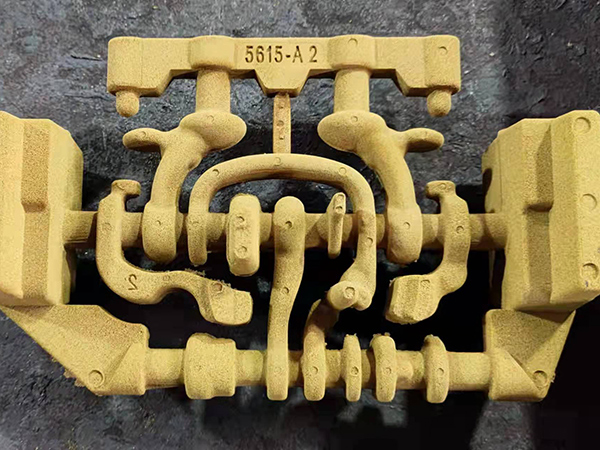

Sand casting is one of the oldest and most versatile manufacturing processes still in widespread use today. It involves creating a mold from a mixture of sand and a binding agent, into which molten metal is poured to form a final product. This technique has proven to be particularly advantageous for several reasons, making it a preferred method in various industries.

Cost-Effectiveness

One of the most compelling reasons for the preference of sand casting is its cost-effectiveness. The materials required for sand casting, particularly sand, are relatively inexpensive and widely available. This makes the process ideal for both small-scale and large-scale production. Furthermore, the setup costs for sand casting are lower than those associated with more complex molding processes, such as investment casting or die casting. This allows manufacturers to produce parts without the need for substantial upfront investment, making it especially appealing for startups and smaller companies.

Versatility

Sand casting can accommodate a broad range of metals, including aluminum, copper, and iron, which are often used in various applications. This versatility is a significant factor in its widespread adoption. Additionally, the sand mold can be created in virtually any shape or size, allowing for the production of both large and complex geometries that may be challenging to achieve using other methods. This flexibility supports a wide array of industries, including automotive, aerospace, and industrial machinery, where customized components are often necessary.

Large Scale Production

While it is well-suited for small batch production, sand casting can also be adapted for larger quantities. Modern technological advancements, such as automated molding processes and efficient sand recycling systems, have enhanced the scalability of sand casting. As a result, manufacturers can produce large volumes of parts without compromising quality or increasing lead times. The ability to produce large-scale quantities without extensive tooling changes further enhances the efficiency of sand casting.

why sand casting is preferred

Ease of Modification

Another advantage of sand casting is its ease of modification. Because the molds are created from sand, adjustments can be made quickly and at a relatively low cost. If a design change is required, the mold can be redesigned with minimal effort, allowing manufacturers to improve their products without the need for significant retooling. This adaptability is crucial in fast-paced industries where product specifications may evolve rapidly due to technological advancements or market demands.

Good Surface Finish and Tolerances

Although sand casting may not be known for achieving the finest surface finishes compared to other methods, it can still produce satisfactory results for many applications. Various techniques, such as sandblasting or grinding, can be employed to enhance the surface finish post-casting. Additionally, while sand casting tolerances can vary, it is possible to achieve fairly tight tolerances with skilled craftsmen and modern machining methods, making it suitable for precision components.

Environmental Benefits

Sand casting also tends to be more environmentally friendly compared to other metalworking processes. Sand is a naturally abundant resource that can be reused multiple times. In contrast, some casting methods produce significant waste materials that need to be disposed of or recycled. The ability to recycle sand makes this process more sustainable in the long run, which is becoming an increasingly important factor for many companies looking to minimize their environmental impact.

Conclusion

In conclusion, sand casting remains a fantastic option for manufacturers looking for an efficient, cost-effective, and versatile casting method. Its adaptability to different metals, economic advantages, scalability, and ease of modification position it as a preferred method for producing complex shapes and components. Moreover, the environmental benefits associated with sand recycling contribute to its continued relevance in modern manufacturing. As industries evolve and new technologies emerge, the enduring strengths of sand casting ensure it will remain a vital part of the manufacturing landscape for years to come.

Post time:Ное . 29, 2024 23:48

Next:Can You Smooth Resin Surfaces Effectively and Achieve a Perfect Finish?