What is Resin Coated Sand?

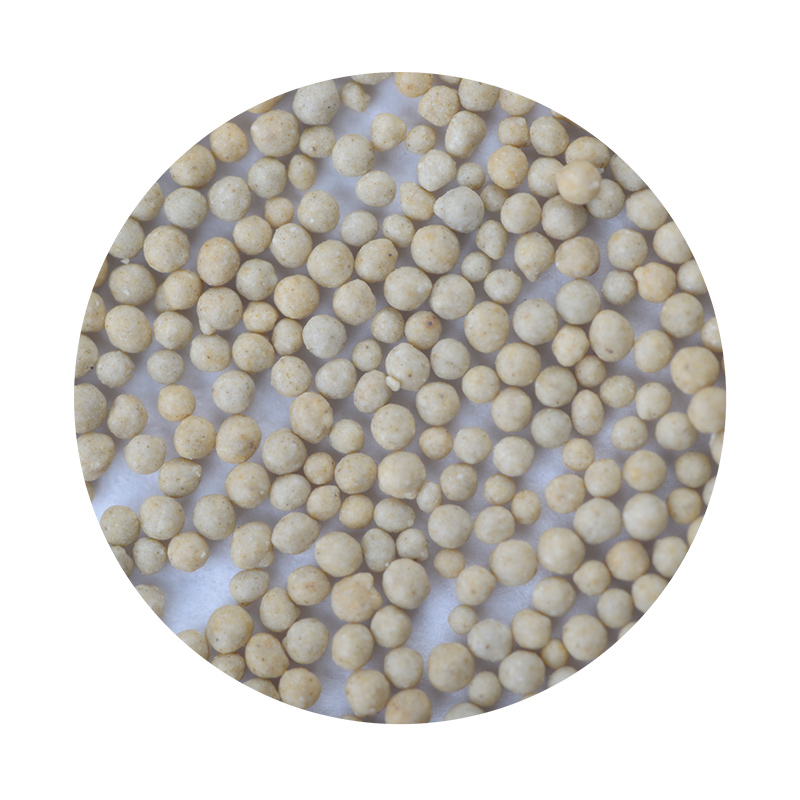

Resin coated sand is a specialized type of sand that has been coated with a resin binder, designed primarily for use in metal casting applications. This innovative material serves as a mold-making medium, which provides several advantages over traditional sand casting methods. To truly grasp the importance of resin coated sand, it’s essential to understand its composition, advantages, and applications within the foundry industry.

What is Resin Coated Sand?

One of the primary advantages of resin coated sand is its ability to produce molds with high dimensional accuracy and smooth surface finishes. Unlike traditional sand molds, which often have a rough texture, resin coated sand molds can closely replicate fine details of complex patterns. This feature significantly reduces the need for further machining or finishing processes, saving both time and costs in production.

what is resin coated sand

Additionally, resin coated sand exhibits excellent resistance to thermal shock and collapses less during the pouring of molten metal, leading to fewer defects in the final casting. This stability helps foundries produce high-quality castings with enhanced structural integrity. The consistent performance of resin coated sand in various temperatures also allows it to be a preferred choice for demanding applications such as aerospace, automotive, and heavy machinery parts.

Moreover, the use of resin coated sand can lead to improved productivity within foundries. The quick setting time of resin binders allows for faster mold production, which is crucial in high-volume production environments. Foundries can create molds more rapidly, leading to shorter lead times and increased output without compromising the quality of the molds.

Environmental considerations also play a significant role in the adoption of resin coated sand. Many modern resins are designed to be more environmentally friendly, reducing the emissions associated with traditional sand casting processes. This shift not only complies with increasingly stringent environmental regulations but also appeals to consumers who prioritize sustainable practices.

In summary, resin coated sand is a versatile and high-performance material that has revolutionized the metal casting industry. With its ability to produce high-quality molds that withstand extreme conditions, it offers numerous benefits, including improved dimensional accuracy, enhanced surface finish, reduced production times, and better environmental compatibility. As technology continues to advance, we can expect to see further innovations and applications of resin coated sand, solidifying its position as a vital component in the future of manufacturing. This evolution reflects the industry’s commitment to enhancing quality and efficiency while minimizing environmental impact, ensuring that resin coated sand will remain a key player in foundry operations worldwide.

Post time:Окт . 13, 2024 12:37

Next:Чаму выкарыстоўваецца пясчанае ліццё для вытворчасці металічных вырабаў