An Overview of Sand Casting Sand Types

Sand casting is a widely utilized manufacturing process that involves pouring molten metal into a mold made of sand to produce various metal parts. This versatile technique is favored across multiple industries due to its ability to create complex shapes and its economic viability. However, the success and quality of the final product largely depend on the type of sand employed in the casting process. In this article, we will explore the various types of sand used in sand casting, their characteristics, and their applications.

1. Silica Sand

Silica sand, or quartz sand, is the most commonly used type of sand in the sand casting process. Its grain composition typically consists of over 90% silica (silicon dioxide), which provides excellent properties for molding. Silica sand features high thermal resilience, allowing it to withstand the extreme temperatures of molten metals without breaking down. Additionally, it possesses good flowability, ensuring that the sand can easily fill the mold cavities for precise detailing. However, silica sand can produce a significant amount of harmful dust during handling, which poses health risks to workers.

2. Green Sand

Green sand is a traditional mold-making material composed of silica sand, clay, water, and other additives. The term green refers to the fact that the sand molds are not baked or cured before use, retaining moisture in the mixture. The clay in green sand serves as a binder that helps hold the mold together, while the moisture allows for flexible, easy shaping and provides a degree of cohesion. This type of sand is favored for its ease of use, cost-effectiveness, and the smooth surface finish it can provide to cast parts. However, it may not be suitable for high-precision or high-temperature applications due to potential shrinkage and deformation.

3. No-Bake Sand

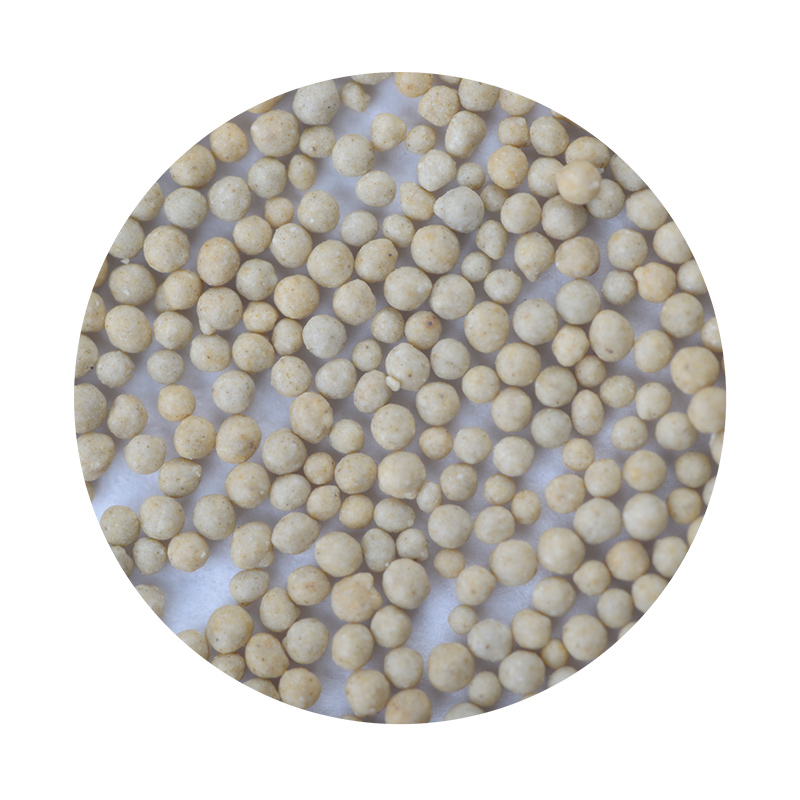

sand casting sand types

No-bake sand, also known as cold box sand, is a mixture of silica sand and a resin binder that hardens when exposed to a catalyst. Unlike green sand, which is influenced by moisture, no-bake sand allows for the creation of complex shapes and finer details due to the added resin. This type of sand is often used when higher precision and dimensional accuracy are required. The molds made from no-bake sand can withstand higher temperatures, making them suitable for casting metals with high melting points, such as aluminum and copper. However, no-bake sand is typically more expensive than traditional green sand.

4. Vinyl Ester Sand

Another innovative type of sand used in casting is vinyl ester sand, which incorporates vinyl ester resin as a binder. This mixture offers improved mechanical properties compared to traditional resins, providing enhanced resistance to heat and chemicals. Vinyl ester sand enables the production of molds that exhibit superior surface finishes and dimensional accuracy. It is often utilized in applications where high-strength parts are required, such as in the automotive and aerospace industries. However, the costs associated with vinyl ester sand can be higher, which must be considered in the manufacturing budget.

5. Zircon Sand

Zircon sand is an advanced casting sand option that offers excellent performance characteristics due to its high melting point and thermal stability. Composed primarily of zirconium silicate, this type of sand is particularly valuable in foundries that handle high-temperature metals or those requiring high-precision molds. Zircon sand reduces the occurrence of metal penetration into the sand mold, resulting in high-fidelity castings. However, its high cost can be a limiting factor for its widespread use, making it more suitable for specialized applications.

Conclusion

Choosing the right type of sand for sand casting is crucial for achieving optimal casting results. Each type of sand has its own unique properties, advantages, and applications, thus influencing the final product's quality and performance. Whether using traditional silica or green sand, advanced no-bake options, or specialized zircons, the selection must align with the specific requirements of the casting project. By understanding the characteristics of each sand type, manufacturers can make informed decisions that enhance casting processes and improve the overall quality of their metal components. As technology evolves, it is likely that new sand variants will emerge, further expanding the possibilities within the realm of sand casting.

Post time:Ное . 15, 2024 01:19

Next:sand 3d