The Process of Sand Casting Duration and Considerations

Sand casting is one of the oldest and most widely used metal casting processes in the manufacturing industry. It involves creating a mold from sand, into which molten metal is poured to create various objects, components, and tools. One common question regarding this process is How long does sand casting take? The answer is multifaceted and depends on several factors.

Understanding the Sand Casting Process

Before delving into the duration of the sand casting process, it is crucial to understand the steps involved. The sand casting process typically includes the following key stages

1. Pattern Creation A pattern, often made of metal, plastic, or wood, is crafted to shape the final product. The complexity of the design significantly impacts the time required for this step.

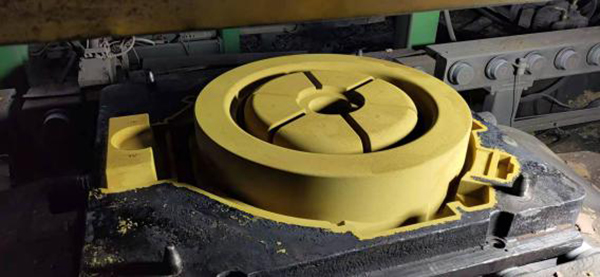

2. Mold Preparation The pattern is pressed into a sand mixture, creating a mold. The sand is usually mixed with a binder to ensure it holds its shape. Time taken for this step will depend on the size and intricacy of the pattern.

3. Mold Assembly Once the molds are made, they are assembled into halves or parts. This can include various cores for internal cavities, which also adds time.

4. Melting and Pouring The metal must be melted, usually in a furnace, before being poured into the mold. The melting time can vary based on the type of metal used and the capacity of the furnace.

5. Cooling and Solidification After pouring, the metal needs time to cool and solidify. This duration varies based on the thickness of the casting and the metal type.

6. Mold Removal and Finishing Once cool, the mold is broken apart, and the casting is cleaned and finished. This can involve processes such as grinding, sanding, or machining.

Factors Influencing Duration

The duration of the entire sand casting process can range from a few days to several weeks, depending on various factors

how long does sand casting take

1. Complexity of Design Intricate designs require more elaborate patterns and molds, increasing the time for pattern creation and mold preparation.

2. Material Selection Different metals have different melting points and cooling rates. For instance, aluminum melts faster than steel, which can affect the overall timeline.

3. Size of the Casting Larger castings take longer to cool and can require more substantial molds, thus prolonging the entire process.

4. Production Scale Smaller production runs usually take longer per unit compared to larger scale manufacturing, as the setup time can be distributed across more parts.

5. Experience and Equipment The proficiency of the workforce and the efficiency of the equipment being used can dramatically influence the speed of each step.

Average Duration

In a typical scenario, sand casting can take anywhere from a few days to a couple of weeks

- Simple Castings For straightforward designs made of materials like aluminum, the process can be completed within 3-5 days. This includes pattern creation, mold preparation, pouring, cooling, and initial finishing.

- Moderately Complex Castings More intricate designs or larger castings can take 1-2 weeks. This additional time accounts for extra complexity in pattern making and cooling.

- Complex Castings For large and complicated castings, the timeframe can extend to several weeks. This might involve additional processes for quality control, further finishing steps, and perhaps additional refining.

Conclusion

In summary, the sand casting process can vary significantly in duration based on numerous factors, including design complexity, material type, casting size, production scale, and the efficiency of the team and equipment involved. While simple castings may be completed in a matter of days, more intricate projects can take weeks to finalize. Understanding these variables is essential for manufacturers and customers alike when planning production schedules and managing expectations. As with any manufacturing process, careful planning and efficient execution can help to minimize lead times while ensuring quality outcomes.

Post time:Дек . 21, 2024 07:24

Next:casting sand for metal