High-Quality Sand Casting An Essential Manufacturing Process

Sand casting, also known as sand mold casting, is one of the oldest and most widely used manufacturing processes for producing metal parts. It involves creating a mold from sand and then pouring liquid metal into that mold to solidify and form the desired shape. High-quality sand casting is critical in various industries, including automotive, aerospace, and heavy machinery, due to its cost-effectiveness, versatility, and ability to produce complex geometries.

The Sand Casting Process

The sand casting process begins with the preparation of the mold. Typically, a mixture of sand, clay, and water is used to create a mold that can hold its shape when packed around a pattern. The pattern is a replica of the final product and can be made from a range of materials, including metal, plastic, or wood. Once the pattern is placed into the sand mixture, the sand is compacted around it to form a mold cavity.

After the mold is prepared, the pattern is removed, leaving a hollow cavity in the sand in the shape of the desired part. The mold is then assembled, and molten metal is poured into it. Depending on the metal being used—such as aluminum, iron, or steel—the casting temperature can vary significantly. Once the metal cools and solidifies, the mold is broken apart to reveal the finished casting.

Factors Influencing Quality

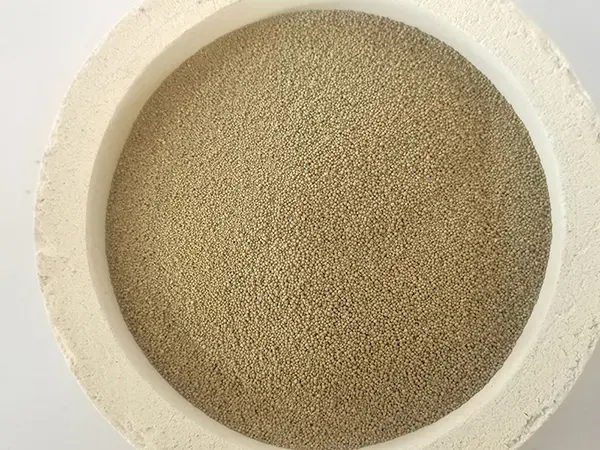

Achieving high-quality sand castings requires careful consideration of several factors. First, the quality of the sand used is paramount. Ideal sand for casting should have good flowability and the ability to retain moisture without falling apart. The composition of the sand, including the type and amount of clay and other additives, can significantly affect the strength and surface finish of the castings.

Secondly, the process parameters during pour and cooling are crucial. Controlling the pouring temperature ensures that the metal flows smoothly into the mold without causing defects such as cold shuts or porosity. Additionally, maintaining an appropriate cooling rate helps prevent internal stresses and cracking, leading to a more durable final product.

high quality sand casting

Another key element is the tooling used for creating the molds. High-precision patterns will yield better-fitting castings, reducing the need for further machining and minimizing waste. Furthermore, proper mold design with appropriate gating systems can enhance the flow of molten metal and improve the overall quality of the casting.

Advantages of Sand Casting

One of the primary advantages of sand casting is its versatility. It can produce large parts and intricate designs that might be challenging for other manufacturing processes. The ability to use a variety of metals also opens up numerous possibilities for custom applications across different industries.

Cost-effectiveness is another significant benefit. Sand casting molds are relatively inexpensive to produce compared to other types of molds used in manufacturing, such as those made from metal. This makes sand casting an attractive option for small to medium-sized production runs where tooling costs need to be kept low.

Applications

High-quality sand casting finds applications in numerous sectors. In the automotive industry, components like engine blocks, cylinder heads, and transmission housings are often sand-cast. The aerospace sector utilizes sand casting for producing components subject to high stress and temperature variations. Additionally, industrial machinery and equipment often rely on durable, high-quality castings produced via this method.

Conclusion

High-quality sand casting is an integral part of modern manufacturing, providing a unique blend of flexibility, cost-effectiveness, and the ability to create complex shapes. As industries continue to evolve, so does the technology and techniques behind sand casting, ensuring that it remains a viable choice for diverse applications. With careful attention to material selection and process control, manufacturers can produce castings that meet strict quality standards, supporting the demands of today’s engineering challenges.

Post time:Дек . 17, 2024 18:58

Next:Resin Coated Sand Manufacturing Facility for Enhanced Casting Performance and Durability