Understanding Sand Casting An Overview of Manufacturers in the Industry

Sand casting is one of the oldest and most versatile casting methods employed in manufacturing today. It involves creating a mold from sand, into which molten metal is poured. As a result, it is often the go-to choice for producing complex shapes and large items, making it essential for various industries, including automotive, aerospace, and heavy machinery. This article explores the world of sand casting manufacturers, highlighting their significance, processes, and the innovations shaping the industry.

The Sand Casting Process

The sand casting process begins with the creation of a pattern, typically made from materials such as wood, metal, or plastic, which determines the final shape of the casting. The pattern is placed in a box, known as a flask, and sand mixed with a binder is packed around it to form the mold. Once the mold is set, the pattern is removed, leaving a cavity that mirrors the design of the pattern.

After forming the mold, molten metal—often aluminum, iron, or bronze—is poured into the cavity. Once the metal solidifies, the sand mold is broken away to reveal the final casting. This process allows for intricate designs and can accommodate both large and small production runs.

Quality and Precision

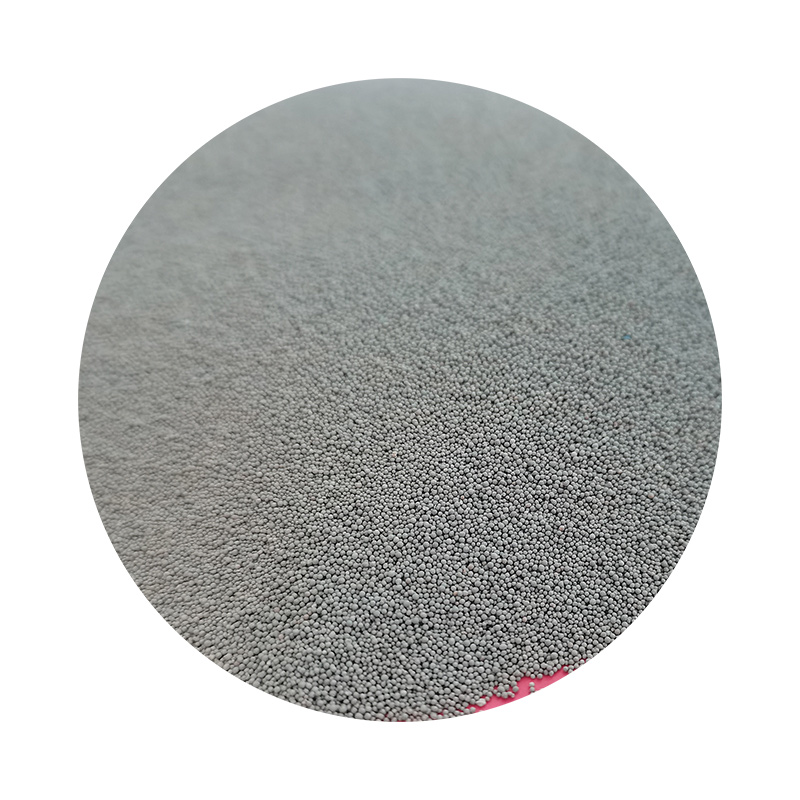

One of the key advantages of sand casting is its ability to produce high-quality, durable parts. Manufacturers take great care to control various factors within the process, such as the type of sand used, the grain size, and the uniformity of the mixture. Advanced technologies, including Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM), enable manufacturers to create precise molds, enhancing the fidelity of the final products. This attention to detail is crucial, especially in applications where reliability and performance are paramount.

The Role of Sand Casting Manufacturers

sand casting manufacturers

Sand casting manufacturers play a vital role in the industry. They bridge the gap between designers and end-users by providing essential services that ensure quality and efficiency. Many manufacturers offer comprehensive services, from designing patterns and molds to finishing the castings to specification. This integrated approach helps streamline the production process, reduce lead times, and minimize costs.

Moreover, suppliers and manufacturers are continuously improving their processes. Many companies invest in research and development to explore new materials, techniques, and sustainable practices. For instance, the introduction of eco-friendly sand alternatives that reduce waste and environmental impact is gaining traction among manufacturers striving for sustainability.

Innovations and Trends

Emerging technologies are rapidly transforming the sand casting landscape. The integration of automation and robotics has significantly improved efficiency and precision. Automated sand preparation systems ensure consistency in sand quality, while robotic pouring systems reduce human error and expedite production.

3D printing technology is another game changer for sand casting manufacturers. It allows rapid prototyping of patterns and molds with complex geometries that were previously difficult or impossible to achieve using traditional methods. By enabling faster iterations, this innovation aids manufacturers in responding promptly to market demands and client requirements.

Furthermore, the industry is witnessing an increased focus on digital transformation. The integration of data analytics and the Internet of Things (IoT) is helping manufacturers optimize their operations and predict potential failures before they occur, thereby reducing downtime and costs.

Conclusion

Sand casting manufacturers are pivotal in producing a wide array of components essential to various industries. Their commitment to quality, innovation, and sustainability positions them well in a competitive market. As technology continues to evolve, these manufacturers will likely adopt new approaches that enhance production capabilities and meet the growing demands of end users. By embracing change and striving for excellence, sand casting manufacturers will continue to thrive and contribute significantly to the global manufacturing ecosystem.

Post time:Rgs . 29, 2024 04:19

Next:Innovative Techniques in 3D Sand Casting for Modern Manufacturing Applications