The Emergence of Sand 3D Printing A Revolution in Manufacturing

In recent years, advances in technology have introduced us to a myriad of innovative manufacturing techniques, among which sand 3D printing stands out as a game-changer, particularly in the fields of construction, art, and industrial applications. This cutting-edge process leverages the unique properties of sand to create precise, durable, and environmentally friendly products, transforming the way we think about production and design.

What is Sand 3D Printing?

Sand 3D printing, often referred to as sand casting or binder jetting, utilizes sand as the primary material for creating three-dimensional objects. The process begins with a computer-aided design (CAD) model that is sliced into layers. A machine then deposits a binding agent selectively onto sand particles to create the desired shape layer by layer. Once the model is complete, the unbound sand is removed, leaving behind a solidified object. This methodology allows for exceptionally detailed features and complex geometries that traditional manufacturing methods struggle to achieve.

Benefits of Sand 3D Printing

One of the most significant advantages of sand 3D printing is its ability to reduce material waste. Traditional sand casting methods often require substantial material to create molds, leading to excess waste. In contrast, sand 3D printing uses only the necessary material needed for the final object, minimizing waste and promoting sustainability. Furthermore, it allows for faster prototyping. Designers can quickly create multiple versions of a product in a fraction of the time it would take using conventional processes. This speed not only enhances creativity but also accelerates the time to market for new products.

Additionally, sand 3D printing is cost-effective for limited production runs and custom projects. Traditional manufacturing methods can be prohibitively expensive for low-volume production due to the high costs of creating molds and tooling. However, because sand 3D printing eliminates the need for these molds, companies can produce small batches economically without sacrificing quality.

Applications in Various Industries

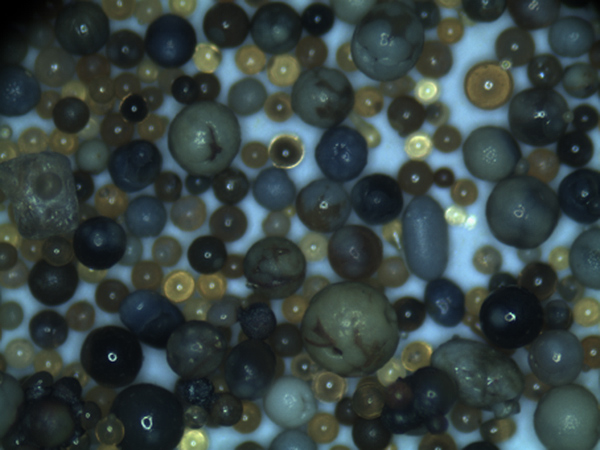

sand 3d print

The versatility of sand 3D printing lends itself to a wide range of applications. In the construction industry, for instance, it paves the way for innovative architectural designs, allowing architects and engineers to experiment with complex structures that were previously unimaginable. The ability to print large-scale structures with sand opens up possibilities for sustainable housing solutions, especially in regions where traditional building materials may be scarce.

In addition, the art world is embracing sand 3D printing to create intricate sculptures and installations that challenge traditional crafting methods. Artists can explore new aesthetics and forms, pushing the boundaries of creativity while utilizing eco-friendly materials.

Sand 3D printing is also making waves in industrial applications, particularly in the manufacturing of metal components. By producing sand molds that are later filled with molten metal, manufacturers can create highly detailed and precise metal parts with reduced lead times. This technology is increasingly being adopted in the aerospace, automotive, and energy sectors, where precision and quality are paramount.

Challenges and Future Prospects

Despite its promising advantages, sand 3D printing does face challenges. The technology requires constant advancements in binder materials to enhance the durability and strength of the final products. Additionally, standardization in the industry could still improve to ensure consistent quality across various applications.

Looking ahead, the future of sand 3D printing is bright. As advancements in technology continue to emerge, we can expect more refined processes and innovative applications that will further integrate this technique into mainstream manufacturing. Research into new materials, including recyclable and bio-based sands, can also enhance the sustainability aspect, positioning sand 3D printing as a pillar of eco-conscious manufacturing.

Conclusion

In summary, sand 3D printing represents a significant leap forward in the realm of manufacturing, offering an environmentally friendly, cost-effective solution that caters to a diverse range of industries. As technology evolves and more sectors adopt this method, we are likely to witness a transformation in how products are made, paving the way for more sustainable, creative, and efficient manufacturing processes. The revolution in sand 3D printing is just beginning, and its full potential is yet to be realized.

Post time:Rgs . 30, 2024 22:37

Next:Contamination des sables de fonderie et ses impacts sur la qualité des produits finis