The Role of Sand in Investment Casting A Comprehensive Overview

Investment casting, also known as lost-wax casting, is a highly versatile and precise manufacturing process used to create complex metal parts. One of the lesser-known, yet crucial, components of this process is the type of sand used for molding. This article explores the significance of sand in investment casting, its characteristics, types, and the impact it has on the final product.

Understanding Investment Casting

Investment casting involves creating a wax pattern of the desired part, which is then coated with a ceramic material to form a mold. The wax is melted and removed, leaving a cavity that is subsequently filled with molten metal. While the primary focus is often on the metal used, the choice of sand for the mold plays a vital role in determining the quality and characteristics of the final casting.

The Importance of Sand in Molding

The primary function of sand in investment casting is to create a support structure for the ceramic shell that encloses the wax pattern. The sand also plays a pivotal role in 1. Thermal Management Sand helps in managing the heat during the cooling process, ensuring that the molten metal solidifies uniformly, which is crucial for dimensional accuracy. 2. Surface Finish The type and quality of sand can significantly affect the surface finish of the final product. A smoother sand typically yields a finer surface finish, which is essential for aesthetic and functional components. 3. Strength and Integrity The mold's strength, determined by the sand used, is essential to withstand the weight of the molten metal and resist any deformation during pouring.

Types of Sand Used in Investment Casting

There are various types of sand used, each with unique characteristics suited for different applications in investment casting

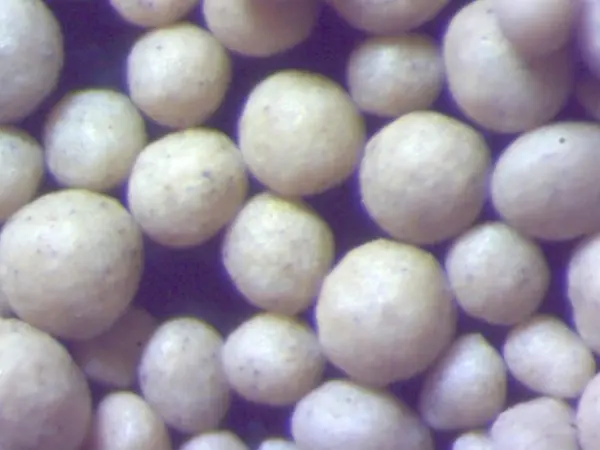

investment casting sand

1. Silica Sand This is the most common type, known for its excellent thermal stability and strength. It can withstand high temperatures, making it suitable for various metal casting applications.

2. Zircon Sand With a higher melting point than silica sand, zircon sand offers superior thermal shock resistance. This type of sand is often used for high-temperature alloys and provides a very smooth surface finish.

3. Chromite Sand Valued for its high resistance to thermal deformation, chromite sand is used in molds that require exceptional strength. It is especially beneficial in casting high-performance components like turbine blades.

4. Olive Sand Rarely used but gaining traction, olive sand is appreciated for its eco-friendly properties. While it doesn't perform as well at extreme temperatures, it’s ideal for less demanding applications.

Conclusion

In investment casting, the selection of sand is a critical factor that can influence the entire casting process. From thermal stability to surface finish, the characteristics of the sand can dictate the quality and durability of the final product. As manufacturers continue to innovate and demand higher precision in their castings, the importance of using the right type of sand cannot be overstated.

Ultimately, while investment casting is often associated with the metals and the technologies used to create them, it's essential to recognize the significant role that sand plays in the overall process. As the industry evolves, ongoing research into new sand types and applications will likely yield even better results, paving the way for advancements in casting technology and high-quality output across various applications.

Post time:Gru . 29, 2024 08:05

Next:resin coated sand manufacturer