Sanding machines provide another valuable resource, particularly for larger projects. Orbital sanders or rotary tools with specific ceramic sanding discs can substantially reduce manual labor and improve sanding consistency. For large installations, investing in such machinery streamlines the process, offering uniformity that hand sanding might struggle to achieve. Safety cannot be overstressed when sanding ceramics. The fine dust generated can be hazardous, necessitating protective gear. A quality dust mask, safety goggles, and gloves protect from dust inhalation and other potential injuries, maintaining a safe working environment. Through my years of refining ceramic surfaces, I've come to understand the importance of getting familiar with your material before starting the process. Each type of ceramic may react differently to sanding efforts, depending on its makeup and glaze. Testing on a small, obscure section helps anticipate how it will respond, allowing for any technique adjustments in advance. The art of ceramic sanding not only revolves around practical techniques but also evolves with the ongoing innovations in ceramic production and treatment. Staying updated with the latest advancements in tools and materials enhances the efficiency and quality of results. This knowledge in sanding ceramics is not merely informational but an authoritative synthesis of years of honing a skill that balances art with practicality. Whether you are a professional or an enthusiast diving into the world of ceramics, mastering these techniques can significantly elevate your projects. Trust that with the right expertise and approach, sanding ceramic surfaces can become both an enjoyable and rewarding endeavor. Post time:ມ.ກ. . 09, 2025 12:14

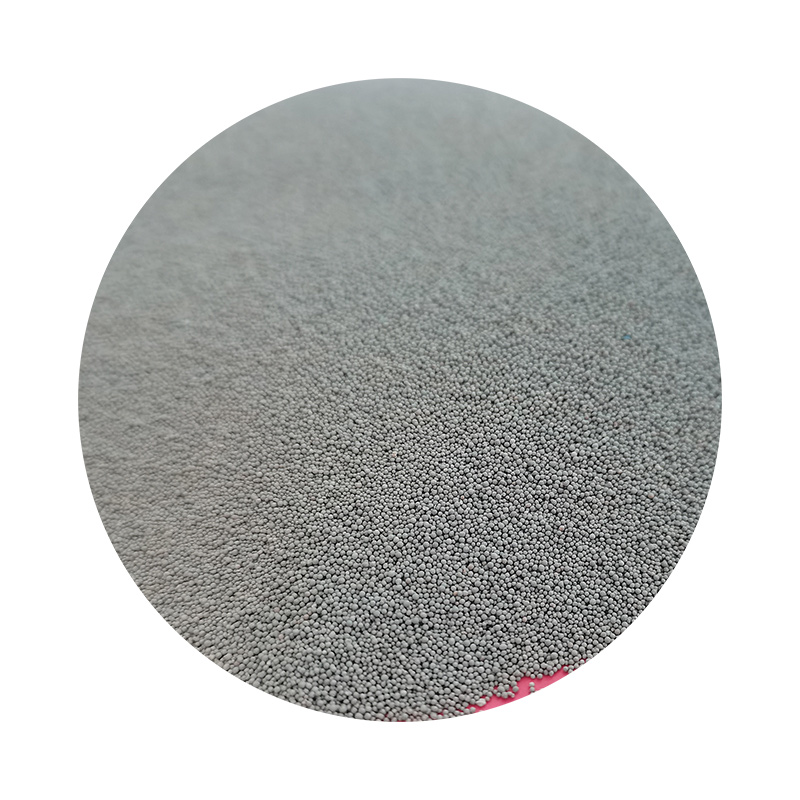

Next:ceramic sand