Sand Casting in Metal Manufacturing A Comprehensive Overview

Sand casting is one of the oldest and most widely used methods of metal casting. It is a versatile and economical manufacturing process that allows for the creation of complex shapes and large metal parts. This article delves into the intricacies of sand casting, its advantages, applications, and the future of this enduring technique.

How Sand Casting Works

The sand casting process begins with the creation of a pattern, which is a replica of the desired final product. Patterns can be made from a variety of materials, including wood, metal, or plastic, depending on the volume of production and the intricacy of the part. Once the pattern is prepared, it is inserted into a mold box, where fine sand mixed with a binding agent, usually clay, is packed around the pattern to form the mold. The sand must be tightly packed to ensure the mold retains its shape during the pouring of molten metal.

After the sand has been compressed, the pattern is removed, leaving a cavity that reflects the shape of the part to be cast. The mold is then carefully assembled, ensuring that all sections fit together properly. Afterward, molten metal is poured into the mold cavity through a channel known as a sprue. The metal fills the cavity and takes the shape of the pattern. Once the metal has cooled and solidified, the sand mold is broken away to reveal the final casting.

Advantages of Sand Casting

1. Versatility Sand casting can be used to create parts of varying sizes and complexities. From small components to large machine parts, sand casting accommodates a wide range of applications.

2. Cost-Effectiveness The raw materials for sand casting are relatively inexpensive, making it a cost-effective choice for production, especially for smaller runs or one-off parts. The reusable nature of the sand also contributes to lower material costs.

3. High Tolerance Sand casting can achieve high levels of dimensional accuracy, making it suitable for precision engineering applications. Modern techniques and advances in technology have further improved this characteristic.

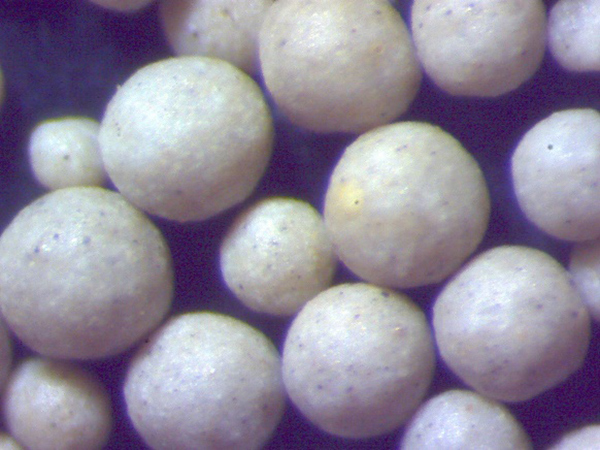

sand cast metal

4. Diverse Material Compatibility This process can accommodate a variety of metals, including iron, aluminum, steel, and copper alloys, allowing manufacturers to choose the most appropriate material for their specific needs.

Applications of Sand Casting

Sand casting is employed across various industries, including automotive, aerospace, and industrial machinery, due to its adaptability. In the automotive industry, for example, components such as engine blocks and transmission cases are often produced using sand casting methods. The aerospace sector utilizes sand casting to fabricate parts that require high strength-to-weight ratios, such as turbine housings and compressor casings.

Moreover, sand casting also finds application in the art and sculpture world, where artists use the technique to create intricate designs in metal. The ability to craft unique, custom pieces is a significant advantage that this method offers.

The Future of Sand Casting

As industries evolve, so too does the sand casting process. Recent advancements, such as 3D printing technology, have begun to play a role in creating more precise patterns and molds. This innovation enhances the efficiency and effectiveness of sand casting, allowing for quicker turnaround times and reduced production costs.

Additionally, the trend towards sustainable manufacturing practices is influencing sand casting operations. Manufacturers are increasingly looking at ways to recycle sand and reduce waste, contributing to a more environmentally friendly production process.

In conclusion, sand casting remains a foundational method in the metal manufacturing industry. Its versatility, cost-effectiveness, and ability to produce complex shapes make it an enduring choice for a variety of applications. As technology advances and industries move towards more sustainable practices, the sand casting process will likely evolve, ensuring its relevance for years to come. Whether in producing large industrial components or intricate art pieces, sand casting will continue to be a pivotal process in metal manufacturing.

Post time:ພ.ຈ. . 30, 2024 02:12

Next:Exploring the Benefits of Incorporating Foundry Sand in Concrete Mixes