The Importance of Choosing the Right Sand Castings Supplier

In the manufacturing and engineering industries, precision and quality are paramount. One of the most critical components that can influence the final product's performance is the casting process, specifically sand casting. This traditional yet effective method is widely used for creating metal parts and components, making the choice of a sand castings supplier vital for success. In this article, we will explore the significance of selecting the right supplier and what aspects to consider.

Understanding Sand Casting

Sand casting is a process that involves creating a mold out of sand to form metal objects. The basic steps include creating a pattern, preparing the sand mold, pouring molten metal into the mold, and finally, allowing it to cool and solidify. Once the metal has hardened, the mold is removed, revealing the cast object. This method is particularly valued for its ability to produce complex shapes and large components with relatively low costs.

Quality Assurance

When selecting a sand castings supplier, quality assurance should be the top priority. A reliable supplier conducts rigorous testing and inspection processes to ensure that all castings meet industry standards. Look for suppliers who are ISO certified or adhere to other relevant quality management systems. High-quality sand castings can enhance the durability and performance of the end product, minimizing the risk of failure during use.

Experience and Expertise

Experience matters in the industry of sand castings. Suppliers with a long history in the field are more likely to possess the expertise necessary to handle complex designs and challenging specifications. They are familiar with potential pitfalls and can provide valuable advice during the design and production phases. Consider suppliers who demonstrate a strong understanding of metallurgy and casting techniques, as their insights can help optimize the casting process.

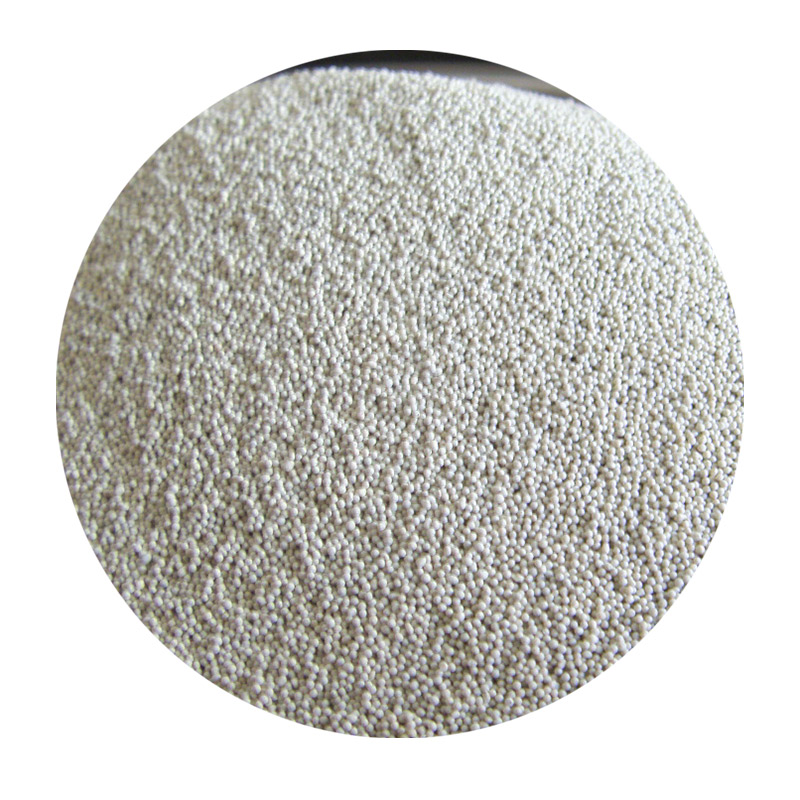

sand castings supplier

Technological Capabilities

As technology continues to evolve, the capabilities of sand casting suppliers also improve. Advanced machinery and techniques, such as 3D printing for pattern-making or automated sand preparation systems, can significantly enhance precision and efficiency. When evaluating a supplier, inquire about their technological investments and how they integrate modern practices into their operations. Suppliers that embrace innovation are likely to provide better quality and faster turnaround times.

Customization and Flexibility

Different projects have unique requirements, and a one-size-fits-all approach is often inadequate. A good sand castings supplier should offer customization options to meet specific needs. This includes the ability to produce various alloys, tolerances, and finishes. Additionally, flexibility in production volume is essential, whether the requirement is for small batches or large-scale production runs. A supplier that can adapt to changing demands will be an invaluable asset to your project.

Ethical and Sustainable Practices

In today’s market, sustainability is becoming increasingly important. Choose a sand castings supplier that adheres to ethical sourcing and environmental practices. This includes using recyclable materials, minimizing waste, and implementing energy-efficient processes. By partnering with suppliers that prioritize sustainability, businesses can contribute to a greener future while also enhancing their corporate reputation.

Conclusion

Choosing the right sand castings supplier is a critical decision that can impact the success of any manufacturing project. By prioritizing quality assurance, experience, technological capabilities, customization, and sustainable practices, businesses can ensure that they partner with a supplier who can meet their needs effectively. With the right supplier, companies can navigate the complexities of sand casting and achieve superior results, leading to long-term success in their respective industries.

Post time:ຕ.ລ. . 09, 2024 01:21

Next:Exploring the Innovations of Sand 3D Printing Techniques and Applications