Lost Foam Casting A Modern Method for Precision Metal Casting

Lost foam casting (LFC) is a unique and efficient method of metal casting that has gained popularity in various manufacturing sectors due to its ability to produce complex shapes with high precision. This process, which utilizes expendable foam patterns, bridges the gap between traditional sand casting and advanced techniques like investment casting, offering both cost-effectiveness and superior surface finishes.

Lost Foam Casting A Modern Method for Precision Metal Casting

Once the foam pattern is prepared, it is coated with a special refractory material, which acts as a sand mold. The foam is then surrounded by loose sand in a molding box, creating a cavity that will take the shape of the original foam pattern. A key aspect of LFC is that the foam is not removed; instead, it vaporizes and leaves behind an empty space into which molten metal can be poured. This vaporization occurs as the metal heats the foam during the pouring process, thus eliminating the need for a traditional core and minimizing fabrication steps.

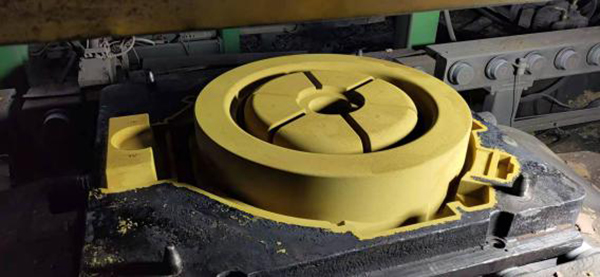

lost foam casting examples

This innovative casting method offers several benefits. One significant advantage is the enhanced design freedom it provides to engineers and designers. The ability to create intricate designs without the constraints typical of other casting methods allows for the production of lightweight components with complex internal cooling channels or structural reinforcements, which are particularly valuable in industries such as aerospace and automotive.

Furthermore, lost foam casting also promotes a reduction in scrap material and the overall weight of the components produced. The process allows for thinner walls in castings, leading to lighter parts without compromising structural integrity. This lightweighting is crucial in applications where reducing weight can lead to improved performance, such as in aircraft and automotive designs, where fuel efficiency is paramount.

Despite its many advantages, the technology is not without its challenges. Achieving consistent quality can sometimes be an issue, as variations in foam pattern density and the coating process can affect the final product’s surface finish and mechanical properties. However, advancements in materials and process controls are continually improving the reliability of lost foam casting.

In conclusion, lost foam casting presents a modern solution for manufacturers looking to achieve high precision and intricate designs in metal components. Its unique approach of utilizing foam patterns not only enhances manufacturing capabilities but also supports the trend toward lighter, more efficient designs in critical industries. As technology continues to evolve, lost foam casting is poised to play an increasingly vital role in the future of metal casting.

Post time:ສ.ຫ. . 31, 2024 07:59

Next:sand cast