The Components of Sand Casting

Sand casting is one of the oldest and most widely used methods of metal casting. This versatile technique is employed to create complex shapes, making it a fundamental process in manufacturing industries such as automotive, aerospace, and heavy machinery. Understanding the components of sand casting is crucial for optimizing the casting process and ensuring high-quality results.

1. Molding Sand

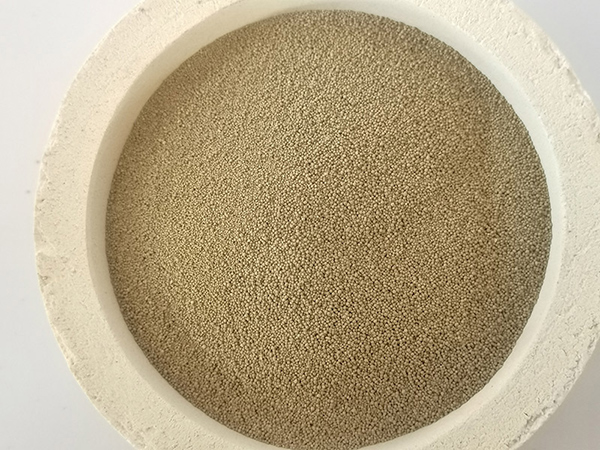

The primary component of sand casting is molding sand. This mixture of silica sand, clay, water, and other additives forms the mold that shapes the molten metal. The most common type of molding sand is green sand, which is a combination of 90% silica sand, 5% to 10% clay, and 2% to 5% water. Clay acts as a binding agent, while water helps to maintain the moisture and workability of the sand.

Green sand is favored for its ability to retain moisture, flexibility, and excellent thermal properties, which allow for the intricate detailing of cast parts. Other types of molding sands include resin-bonded sands and sodium silicate sands, which are often used for specific applications due to their higher strength and precision characteristics.

2. Patterns

Patterns are replicas of the final product and serve as a template for creating the mold cavity. They can be made from various materials, including wood, metal, or plastic, and come in different designs such as solid patterns, split patterns, or core patterns. The choice of pattern material and design greatly influences the cast’s surface finish and dimensional accuracy.

The construction of patterns must consider factors such as thermal expansion and withdrawal post-cooling. Careful design ensures that the cast part aligns accurately with the pattern, minimizing defects and enhancing the final product's quality.

3. Cores

components of sand casting

Cores are utilized to create internal cavities and complex geometries within the cast product. They are typically made from specially formulated sand mixtures and are placed in the mold before pouring the metal. Cores can be either permanent or expendable, depending on the casting requirements.

The use of cores allows for the production of components such as engine blocks with intricate cooling passages or complex shapes that cannot be achieved with a simple two-part mold. Cores must be designed to withstand the heat of the molten metal while maintaining structural integrity.

4. Molten Metal

The molten metal is the primary component that fills the mold cavity to form the final product. Various metals can be used in sand casting, including aluminum, stainless steel, cast iron, and bronze. The choice of metal depends on the required mechanical properties, corrosion resistance, and application of the cast part.

The pouring process requires careful control of temperature and flow rate to prevent defects such as porosity or cold shuts. Proper pouring techniques ensure that the molten metal fills the mold completely and evenly.

5. Finishing Processes

Once the casting has cooled and solidified, it undergoes several finishing processes to achieve the desired surface quality and dimensional accuracy. Common finishing techniques include sand blasting, machining, and painting. These processes remove excess material, improve surface finish, and prepare the part for final assembly or use.

In conclusion, sand casting is a critical manufacturing process consisting of several essential components molding sand, patterns, cores, molten metal, and finishing processes. Understanding the role of each component allows manufacturers to optimize the casting process, producing high-quality, intricate, and durable components for various applications. As industries continue to evolve, innovations in sand casting techniques and materials are likely to enhance its efficiency and effectiveness further, maintaining its status as a cornerstone of modern manufacturing.

Post time:ທ.ວ. . 24, 2024 17:12

Next:A Guide to Creating Your Own Foundry Sand at Home