The Revolutionary Role of 3D Printer Sand in Modern Manufacturing

In recent years, 3D printing technology has transformed various industries, providing innovative solutions for manufacturing, design, and prototyping. One of the most intriguing and versatile materials that have emerged within this realm is sand. The incorporation of sand into 3D printing processes heralds a new era of sustainable practices, efficiency, and creativity. This article explores the myriad applications and benefits of 3D printer sand, shedding light on its potential impact on industries ranging from construction to art.

Understanding 3D Printer Sand

3D printer sand typically refers to a mixture of fine sand grains that can be bound together using a variety of binding agents, making it suitable for additive manufacturing processes. This technique often involves a method called binder jetting, where layers of sand are spread across a build platform, and an adhesive agent is selectively sprayed, solidifying the material into a desired shape. Unlike traditional casting methods, which require molds, 3D printing with sand allows for intricate designs and rapid prototyping without the need for extensive tooling.

Sustainable Manufacturing

One of the most compelling advantages of using sand in 3D printing is its sustainability. Traditional manufacturing practices often rely on non-renewable resources and contribute significantly to pollution and waste. In contrast, sand is abundant and can often be sourced locally, minimizing transportation costs and energy consumption. Furthermore, the additive nature of 3D printing means that material is only used where necessary, reducing waste to a fraction of that produced by conventional methods. This aligns with the growing demand for environmentally responsible manufacturing processes and supports the global shift toward sustainability.

Applications in Construction

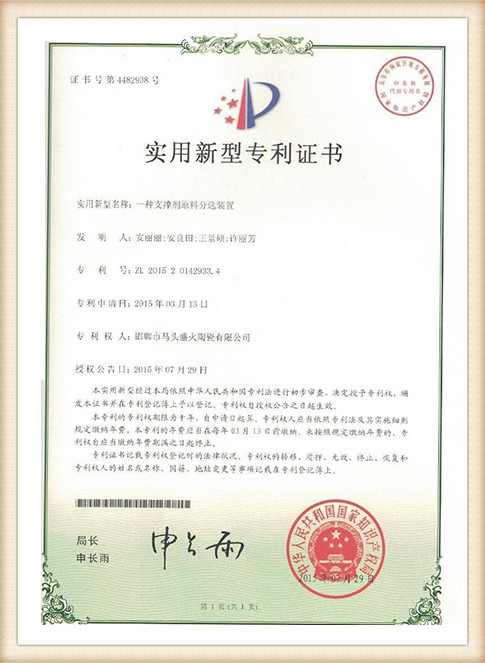

3d printer sand

The construction industry stands to benefit considerably from 3D printing with sand. The potential to create intricate and robust structures on-site reduces the need for heavy machinery and minimizes transportation difficulties associated with traditional building materials. Some innovative projects have even explored using sand to create entire buildings, leveraging local materials and reducing construction time. This capability not only streamlines the building process but also allows for greater design flexibility, enabling architects and builders to create complex forms that would be challenging to achieve through traditional methods.

Advancements in Art and Design

Artists and designers are also beginning to embrace the use of sand in 3D printing. The unique textures and finishes that can be achieved with sand-based printing offer an exciting avenue for creativity. Sculptors can create detailed works without the constraints of conventional carving or molding techniques. Additionally, sand's natural properties can be utilized to create eco-friendly art installations that resonate with themes of nature and sustainability. As artists experiment with this medium, we can expect to see a surge of innovative, thought-provoking works that redefine contemporary art.

Challenges and Future Directions

While 3D printing with sand presents numerous advantages, challenges remain. The need for specialized equipment and materials can deter small businesses from entering this space. However, ongoing advancements in technology and the decreasing costs of 3D printing systems are making these solutions increasingly accessible. Moreover, ongoing research into improving the binding agents and enhancing the structural integrity of sand-based prints will expand the material's applications and inspire even more innovative uses.

Conclusion

In conclusion, 3D printer sand represents a significant advancement in manufacturing technology, merging sustainability with creativity and efficiency. Its applications in construction and art highlight the versatility of this material, as industries increasingly look for ways to innovate and reduce their environmental footprint. As the technology continues to evolve and more businesses adopt these practices, 3D printing with sand has the potential to reshape the landscape of manufacturing, offering exciting possibilities for the future. As we embrace these new methodologies, the synergy between technology and sustainability will pave the way for a more responsible and innovative world.

Post time:ທ.ວ. . 13, 2024 21:35

Next:casting sand suppliers