The Importance of Sand Casting in Chinese Manufacturing

China has long been recognized as a global leader in manufacturing, and one of the key techniques that underpin its industrial prowess is sand casting. This method, known for its versatility and cost-effectiveness, has been widely adopted by numerous factories across the country. The process of sand casting involves creating a mold from sand to produce metal parts, making it an essential component in various industries, including automotive, aerospace, and heavy machinery.

What is Sand Casting?

Sand casting is a process where a pattern of the desired metal object is created, usually using wood or metal. This pattern is then placed in a mixture of sand and binder, forming a mold. Once the mold is set, molten metal is poured into it, allowed to cool, and then the mold is broken away to reveal the cast part. This method allows for the production of complex shapes and sizes while maintaining a high level of precision.

Advantages of Sand Casting

One of the primary advantages of sand casting is its cost-effectiveness, particularly for large batch productions. The materials required for sand molds are inexpensive and readily available, making it a favored choice among manufacturers. Additionally, the sand can be reused for multiple castings, further reducing costs and waste.

Another significant benefit is the flexibility of the sand casting process. It can accommodate a wide variety of metals, including iron, aluminum, bronze, and magnesium alloys. This versatility allows Chinese manufacturers to produce a vast array of products, catering to both domestic and international markets.

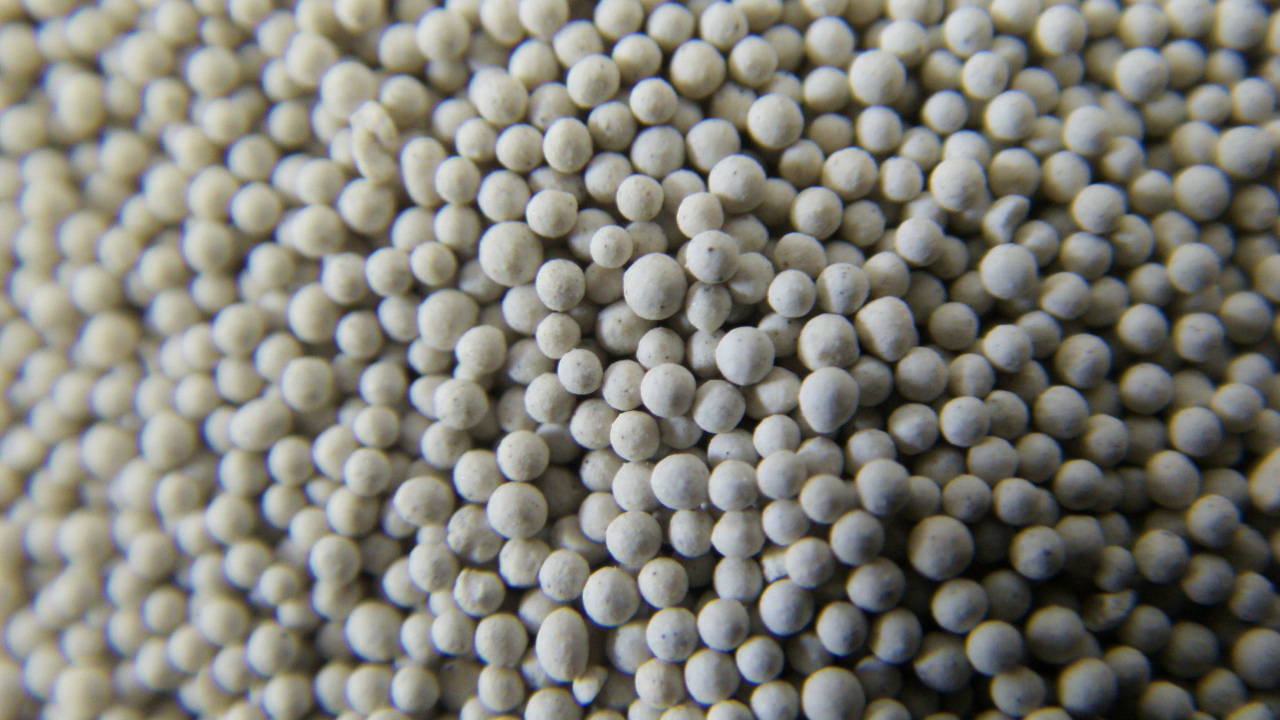

china sand casting factory

The Role of Sand Casting Factories in China

China’s sand casting factories play a vital role in the global supply chain. They employ advanced technologies and methodologies to enhance production efficiency and quality. Many factories have adopted automation and digital controls, which streamline the molding and casting processes, leading to improved consistency and reduced lead times.

Moreover, these factories are often situated in close proximity to major industrial hubs, providing convenient access to suppliers and customers alike. This geographic advantage further enhances their ability to respond quickly to market demands, whether it be for short-run prototypes or large volume orders.

Quality and Standards

In recent years, Chinese sand casting factories have placed a greater emphasis on quality control and compliance with international standards. Many have obtained certifications such as ISO 9001, ensuring that their products meet global quality benchmarks. This commitment to quality not only bolsters the reputation of Chinese manufacturers but also instills confidence in international customers seeking reliable suppliers.

Conclusion

Sand casting remains a cornerstone of China's manufacturing industry, combining affordability, versatility, and efficiency. As technology continues to advance, Chinese sand casting factories are poised to maintain their competitive edge while meeting the evolving needs of the global market. Whether producing intricate automotive components or large industrial parts, the sand casting method exemplifies how traditional techniques can be adapted to modern manufacturing challenges, securing China’s position as a powerhouse in the global manufacturing landscape.

Post time:Oct . 08, 2024 03:00

Next:Смысл литья песка