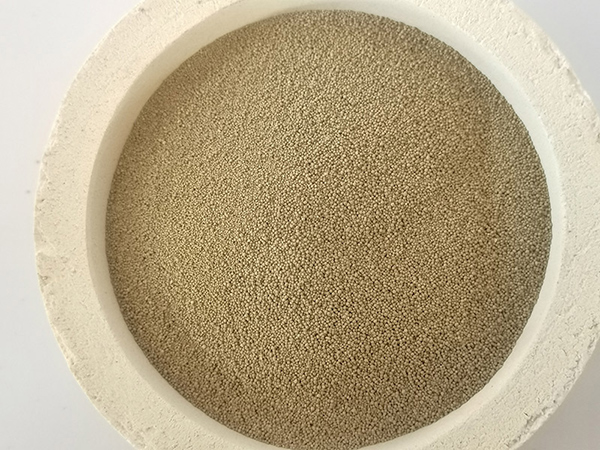

What is Resin Coated Sand?

Resin coated sand (RCS) is a specialized material widely used in the metal casting industry. This unique type of sand is coated with a resin that enhances its performance in various applications, particularly in the creation of high-quality molds and cores for metal casting. Understanding the composition, advantages, and applications of resin coated sand is crucial for industries looking to optimize their casting processes and improve the quality of their final products.

Composition

Resin coated sand typically consists of high-quality silica sand that is coated with a thermosetting resin. The resins most commonly used in this process include phenolic, furan, and epoxy resins. The coating process involves mixing the silica sand with the resin and a catalyst, which triggers the hardening reaction. Once the sand is uniformly coated, it is cured to ensure that the resin bonds effectively with the sand grains. This process results in improved strength and thermal stability, making RCS an excellent material for creating precise and durable molds.

Advantages

The use of resin coated sand offers several advantages over traditional sand casting methods. Here are some of the key benefits

1. Higher Mold Strength RCS exhibits superior strength compared to conventional sand, allowing for thinner and more intricate mold designs. This increased strength reduces the likelihood of mold collapse during the casting process.

2. Improved Surface Finish The smooth and uniform surface provided by RCS results in a better surface finish for the casted parts. This is particularly crucial for industries that require high-precision components with minimal post-processing.

3. Precision and Detail The ability to capture fine details in the mold is enhanced with RCS. This makes it ideal for complex shapes and intricate designs that would be difficult to achieve with traditional sand.

4. Reduced Environmental Impact Many manufacturers are shifting towards using resin coated sands that are free from harmful materials, thus minimizing their environmental footprint. RCS can often be recycled, making it a more sustainable choice compared to conventional sand.

what is resin coated sand

5. Faster Production Times The quick curing processes associated with resin coated sands enable faster production cycles. This efficiency allows for shorter lead times and increased output, an essential factor in today’s competitive manufacturing landscape.

Applications

Resin coated sand is extensively used across various industries, particularly where precision and quality are paramount. Some key applications include

- Automotive Industry RCS is widely used in the production of engine blocks, cylinder heads, and various other automotive components. The strength and finish of the castings produced using RCS meet the stringent requirements of automotive manufacturing.

- Aerospace Industry The aerospace sector demands high-quality components that must endure extreme conditions. RCS offers the necessary precision and reliability for producing critical aerospace components.

- Industrial Machinery Various heavy equipment and machinery parts are manufactured using resin coated sand, as it can support the production of large, complex shapes with a high degree of detail.

- Artistic and Sculptural Casting Artists and sculptors also benefit from RCS as it allows them to create detailed and exceptionally crafted works in metal, capturing intricate details that traditional methods may not achieve.

Conclusion

In conclusion, resin coated sand is a versatile and advantageous material that has revolutionized the metal casting industry. Its unique composition provides numerous benefits, from increased strength and precision to environmental sustainability. As industries continue to evolve and demand higher-quality components, the adoption of resin coated sand is likely to increase, driving innovation and efficiency in casting processes. Whether in automotive, aerospace, or artistic applications, RCS stands out as a superior choice, fulfilling the needs of modern manufacturing while paving the way for future advancements in casting technology.

Post time:11월 . 14, 2024 20:04

Next:casting sand suppliers