The Importance of Sand in the Foundry Industry

In the realm of metallurgy and manufacturing, few materials are as vital as sand. Foundries, establishments dedicated to casting metal parts, heavily rely on sand for the creation of molds used in metal casting processes. The use of sand in foundry applications is not just about utility; it’s about precision, quality, and the overall effectiveness of casting operations.

Types of Sand Used in Foundries

The most commonly utilized sand in foundries is silica sand, known for its high melting point and thermal stability. Silica sand is primarily composed of silicon dioxide (SiO2) and is favored for its ability to withstand high temperatures without breaking down or fusing. Each foundry may use different grades of silica sand depending on the specific requirements of the casting process being employed.

Another type of sand used in foundries is olivine sand, which is derived from magnesium iron silicate. Olivine sand is characterized by its high refractoriness and low thermal expansion, making it suitable for casting molten metals like steel, iron, and aluminum. Furthermore, it produces castings with smooth surfaces and fine details, enhancing the overall quality of the final product.

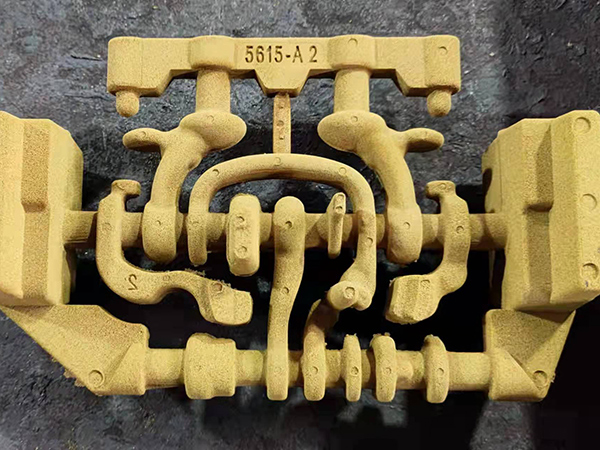

Petroleum-based sands, often treated with resin, are also becoming popular due to their superior binding properties. This type of sand is particularly useful in the production of complex shapes and intricate designs, as it offers excellent strength and a smooth finish. Each type of sand has unique characteristics that cater to specific casting needs, underscoring the importance of selecting the right material for every project.

The Sand Casting Process

Sand casting is one of the oldest and most widely used casting processes in the foundry industry. The procedure begins with creating a mold from a pattern, typically made of metal, wood, or plastic. The mold is formed by packing sand around the pattern to create a cavity, which is then removed to leave an impression. The two halves of the mold are then fitted together, and molten metal is poured into the cavity.

sand used in foundry

One of the critical stages of sand casting is the preparation of the sand itself. The sand must retain its shape while holding the molten metal, which requires a careful balance between moisture content and the grain size of the sand. A well-prepared sand mixture not only ensures that the mold maintains its integrity but also minimizes defects in the final casting.

Reclamation and Environmental Considerations

As the foundry industry evolves, so too does its approach to sustainability and environmental practices. The reclamation of used sand is a growing trend in many foundries, where spent sand is processed and reused for future casting operations. This not only reduces waste but also lowers production costs associated with acquiring fresh sand.

In addition to reclamation, foundries are increasingly exploring alternative sand materials that have less environmental impact. Natural sands and synthetic sands that replicate the properties of traditional silica sand without the associated mining activities are gaining traction. By focusing on sustainability, foundries not only benefit the environment but also improve their market competitiveness.

Conclusion

Sand is an indispensable component of the foundry industry, playing a pivotal role in shaping the future of metal casting. The varying types of sand, their applications, and the careful processes of sand casting all reflect the intricate relationship between this humble material and the sophisticated world of manufacturing. With the added emphasis on sustainability and environmental responsibility, the use of sand in foundries is poised to adapt and evolve, ensuring a balance between operational efficiency and ecological stewardship.

As the foundry industry continues to innovate, the role of sand will remain central to its processes. Whether through advancements in sand technology, reclamation methods, or the development of alternative materials, sand will continue to be a fundamental element in the creation of high-quality metal castings, illustrating its enduring importance in industrial applications.

Post time:11월 . 08, 2024 19:50

Next:ceramsite foundry sand