Understanding Resin-Bonded Sand Casting A Comprehensive Overview

Resin-bonded sand casting is increasingly gaining prominence in the foundry industry due to its unique benefits and applications. This advanced technique combines traditional sand casting methods with synthetic resin, paving the way for improved mold strength, precision, and surface finish. In this article, we will delve into the fundamental concepts of resin-bonded sand casting, its advantages, the process, and its applications across various industries.

What is Resin-Bonded Sand Casting?

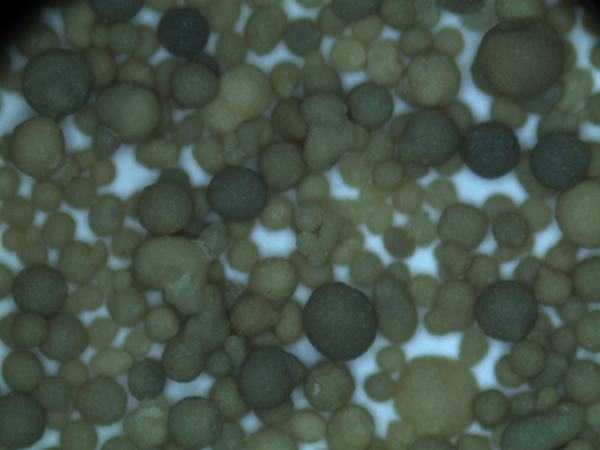

Resin-bonded sand casting involves the use of specially formulated resin to bind sand particles together, creating a mold that captures intricate details and specifications required in the casting process. This differs from traditional sand casting, where sand is typically bonded using water and clay. The result is a mold that possesses enhanced durability and allows for tighter tolerances, making it suitable for producing complex geometries and thinner sections.

The Process of Resin-Bonded Sand Casting

The process of resin-bonded sand casting typically involves several key steps

1. Preparation of the Core and Molds The first step is to prepare the sand mixture, which consists of sand grains and a resin binder. The mixture is usually blended with a hardener, which initiates the curing process once the mold is formed.

2. Mold Creation The mixed sand is then compacted into the desired shape using a molding machine. The resin is activated, causing it to bond the sand particles together. The resultant mold is then allowed to cure, achieving a solid structure capable of withstanding the pouring of molten metal.

3. Casting Once the mold is prepared and properly cured, molten metal is poured into the cavity of the mold. This step demands precision to ensure that the metal fills the mold uniformly without leaving any voids or defects.

4. Cooling and Finishing After the metal has cooled and solidified, the mold is broken apart to retrieve the cast component. This initial piece may require additional finishing processes, including grinding, machining, and surface treatment, to meet the final specifications.

Advantages of Resin-Bonded Sand Casting

The use of resin in sand casting offers numerous advantages over traditional methods

resin bonded sand casting

- Enhanced Strength and Durability The resin provides superior bonding, resulting in mold strength that can withstand the high temperatures and pressures encountered during casting.

- Improved Surface Finish Resin-bonded sand molds typically produce cleaner and smoother surfaces, reducing the need for extensive post-casting finishing

.- Precision and Accuracy The ability to create intricate mold designs allows for high levels of detail and precision in cast products, making it ideal for complex shapes.

- Reduced Environmental Impact Unlike traditional sand casting methods that rely on clay and water, resin-bonded sand casting can be more environmentally friendly due to the lower consumption of resources and waste materials.

Applications of Resin-Bonded Sand Casting

Resin-bonded sand casting is widely utilized across various sectors, including

- Automotive Industry This method is ideal for producing engine components, transmission cases, and other intricate parts that require high accuracy and durability.

- Aerospace Industry The lightweight and strong alloys produced through resin-bonded sand casting are essential for aircraft components, contributing to fuel efficiency and performance.

- Marine Applications The method is used to create critical parts for marine engines and structures, where corrosion resistance and strength are paramount.

- Industrial Machinery Components used in heavy machinery, such as gears and housings, benefit from the precision and surface quality of resin-bonded sand cast products.

Conclusion

Resin-bonded sand casting represents a significant advancement in the realm of casting technologies. Its ability to produce intricate designs with superior finish and strength makes it an exceptional choice for various industrial applications. As the foundry sector continues to evolve, the adoption of this innovative method will likely expand, promoting efficiency and sustainability in manufacturing processes. Whether it's in automotive, aerospace, or heavy machinery, resin-bonded sand casting is poised to remain a vital technique in modern casting practices.

Post time:ನವೆಂ . 25, 2024 11:35

Next:properties of foundry sand