The Difference Between Die Casting and Sand Casting

Casting is a fundamental manufacturing process used to create a wide variety of metal parts and components. Among the many casting methods, die casting and sand casting are two of the most widely employed techniques, each with its own unique advantages and disadvantages. Understanding the differences between these two casting methods is essential for manufacturers to choose the right technique for their specific applications.

Die Casting

Die casting is a precision casting process that involves injecting molten metal into a mold under high pressure. The molds used in die casting, also known as dies, are typically made from steel or other durable materials capable of withstanding high pressures and temperatures. As the molten metal is forced into the mold, it rapidly cools and solidifies, resulting in a finished part that often requires little to no machining.

One of the most significant advantages of die casting is its ability to produce high-volume, complex parts with excellent surface finish and dimensional accuracy. This makes die casting particularly popular in industries such as automotive, electronics, and consumer goods, where the need for precision and consistency is paramount. Additionally, the quick cooling process allows for faster production cycles, making it a cost-effective choice for large-scale manufacturing.

However, die casting has its limitations. The initial setup costs can be high, as creating a die is a significant investment. Moreover, die casting is best suited for non-ferrous metals, such as aluminum, zinc, and magnesium, which can restrict its applications in certain industries that utilize ferrous metals.

Sand Casting

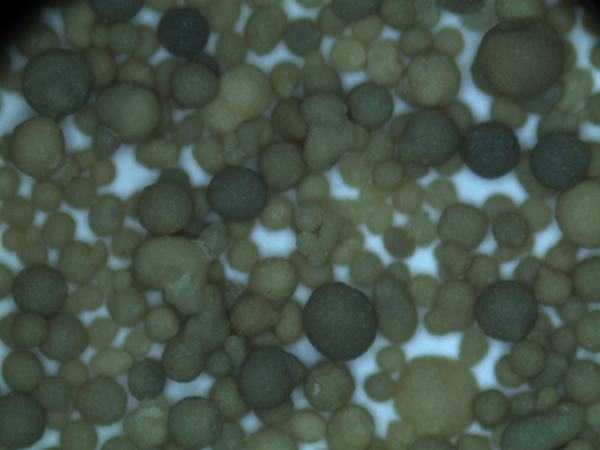

difference between die casting and sand casting

In contrast, sand casting is a more traditional and versatile method that involves creating a sand mold to hold the molten metal. The process begins with a pattern, usually made from wood or metal, which is pressed into sand mixed with a bonding agent to form a mold. Once the pattern is removed, the mold is assembled, and molten metal is poured in to create the desired part.

Sand casting offers several benefits, especially in terms of flexibility. It can accommodate a wide range of metals, including both ferrous and non-ferrous materials, making it suitable for diverse applications. The mold itself can be more easily modified or rebuilt for different parts, making sand casting ideal for low-volume production and prototyping. Additionally, the initial setup costs are generally lower than die casting, making it a more accessible option for small businesses or startups.

However, sand casting tends to produce parts with rougher surface finishes and lower dimensional accuracy compared to die casting. The cooling time is also longer, which can slow down production rates. As a result, sand casting is often preferred for larger, simpler parts where extreme precision is not critical.

Conclusion

In summary, both die casting and sand casting are valuable manufacturing processes with distinct characteristics. Die casting excels in producing high-volume, precision parts with excellent surface finish, but it comes with higher initial costs and limitations on metal types. Sand casting, on the other hand, offers flexibility and lower startup costs, but it may compromise on surface finish and accuracy.

Manufacturers must carefully evaluate their project requirements, production volumes, and budget constraints to select the most appropriate casting method. By understanding the differences between die casting and sand casting, businesses can make informed decisions that enhance their manufacturing capabilities and meet their clients' needs effectively.

Post time:ಡಿಸೆ . 30, 2024 03:23

Next:Exploring Techniques for Foundry Sand Quality Assessment and Testing Methods