Exploring the Exciting World of 3D Printing with Sand

In recent years, 3D printing technology has revolutionized various industries, paving the way for innovative applications and creative solutions. Among the many materials employed in this cutting-edge manufacturing process, sand has emerged as a remarkable medium, particularly in the construction and art industries. This article delves into the fascinating world of 3D printing with sand and its potential to reshape our understanding of production, design, and sustainability.

3D printing with sand primarily involves the use of a binder jetting technique, where a liquid binder is selectively deposited onto layers of sand to create solid structures. This process allows for incredible precision and complexity in designs that would be impossible to achieve with traditional methods. The ability to print intricate shapes has made sand a favored material in industries such as architecture, automotive, and even aerospace.

Exploring the Exciting World of 3D Printing with Sand

In architecture, 3D printing with sand is transforming the way we conceptualize and construct buildings. Architects can create complex designs that are not only aesthetically pleasing but also structurally sound. By utilizing computer-aided design (CAD) software, architects can visualize their concepts in three dimensions and optimize them for 3D printing, leading to unique structures that challenge traditional architecture norms. This method can reduce construction time and costs while enabling the fabrication of custom-designed components on-site, potentially revolutionizing how we approach housing and building projects.

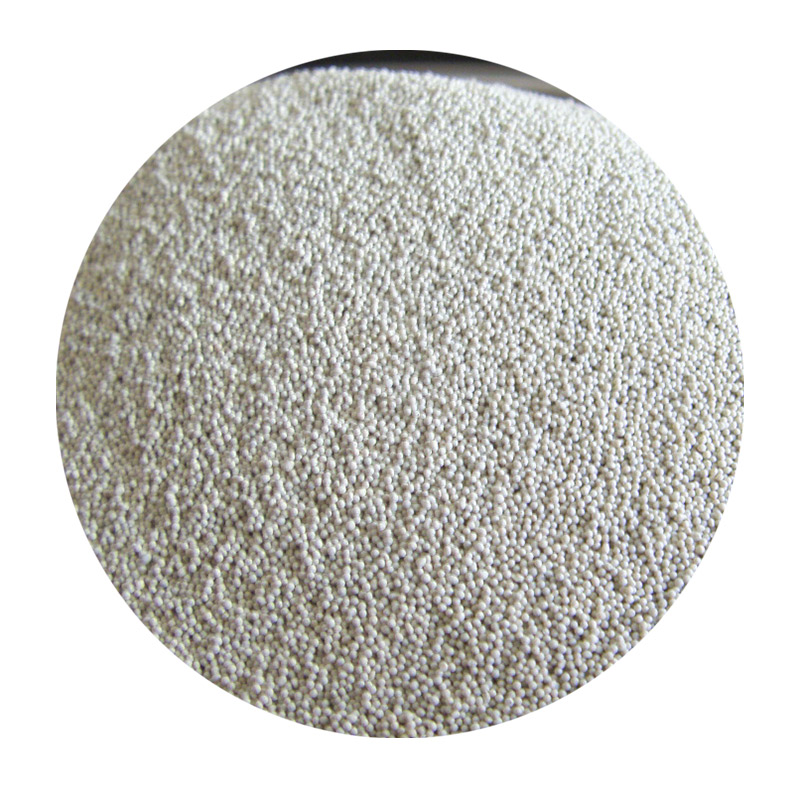

3d printing sand

Moreover, the automotive and aerospace industries are exploring the potential of sand-based 3D printing for producing lightweight yet durable components. Traditional manufacturing methods often come with significant limitations regarding design complexity and material efficiency. However, the layer-by-layer approach of 3D printing allows for the creation of geometrically complex parts that can significantly reduce weight without compromising strength. This aspect can lead to improved fuel efficiency and performance, marking a considerable advancement in engineering and design.

Beyond industrial applications, 3D printing with sand opens new avenues for artists and designers. The ability to create detailed sculptures and installations using sand allows for experimentation with forms previously unachievable through conventional techniques. Artists can leverage the flexibility of 3D printing to push the boundaries of creativity, producing bespoke pieces that capture the imagination and showcase the beauty of sand as a medium.

Despite its many advantages, challenges remain in the field of sand-based 3D printing. Variability in sand quality, the need for specialized equipment, and the requirement for effective post-processing techniques are hurdles that must be addressed for widespread adoption. However, ongoing research and developments in materials science are paving the way for improvements that could enhance the feasibility and accessibility of this technology.

In conclusion, 3D printing with sand represents a thrilling intersection of innovation, sustainability, and creativity. As this technology continues to evolve, it promises to shape industries, redefine construction practices, and inspire a new generation of artists. By harnessing the power of sand as a 3D printing material, we are not only creating exciting opportunities for the future but also taking meaningful steps towards more sustainable and efficient manufacturing practices. Embracing this technology could indeed change the landscape of production for generations to come.

Post time:ನವೆಂ . 12, 2024 01:01

Next:sand casting iron