Understanding Sand Casting Prices A Comprehensive Overview

Sand casting, also known as sand mold casting, is a widely used metal casting process that employs granular sand as the mold material. This method offers an efficient way to create complex shapes with a high-quality surface finish, making it a popular choice across various industries, including automotive, aerospace, and machinery manufacturing. However, understanding the cost associated with sand casting is crucial for businesses and individuals looking to invest in this manufacturing technique.

Factors Influencing Sand Casting Prices

1. Material Costs The cost of raw materials significantly affects the overall price of sand casting. Common materials used in sand casting include aluminum, iron, and bronze. Each of these materials varies in price, influenced by market demand and availability. For instance, fluctuations in the price of aluminum can lead to considerable changes in the quoted price for sand casting projects.

2. Complexity of the Design The complexity of the part being produced is another critical factor. More intricate designs require additional time and resources, leading to higher costs. This includes the need for more detailed patterns, intricate cores, and more extensive finishing processes to meet specifications.

3. Size of the Casting The dimensions of the mold play a significant role in pricing. Larger castings require more material and have longer cycle times, which can add to the overall cost. Conversely, smaller castings typically incur lower costs, although the setup time for both may not differ significantly.

4. Production Volume The scale of production is also vital. High-volume production runs can benefit from economies of scale, often reducing the per-unit cost. On the other hand, small batch productions can lead to higher individual piece costs, as the fixed costs of setup and labor are spread over fewer units.

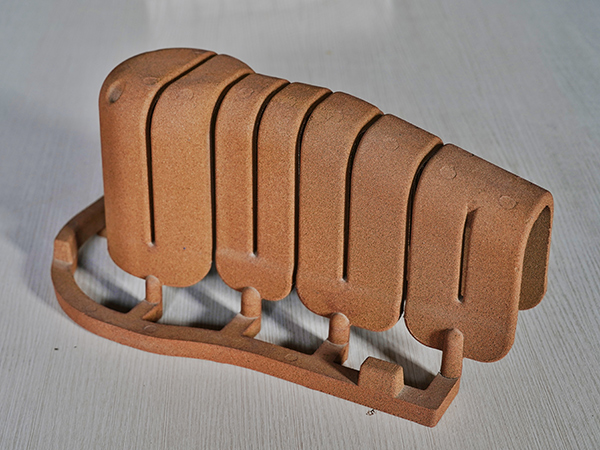

sand casting price

5. Labor Costs The skill level and experience of the workforce involved in sand casting can influence prices. Highly skilled workers may demand higher wages, impacting the overall cost of the casting process. Additionally, regions with higher labor costs due to living expenses will generally see higher casting prices.

6. Lead Times Urgency can affect pricing as well. If a project requires expedited production, manufacturers may charge a premium to prioritize the order. This is often seen in industries where downtime or delays can result in significant financial losses.

Benefits of Sand Casting Despite Costs

While sand casting prices can vary based on the factors mentioned above, it remains a preferred choice for many manufacturers due to its versatility and economic advantages. It allows for high customization, quick turns for prototype development, and is capable of producing complex geometries that other casting methods may struggle to achieve.

Furthermore, sand casting is compatible with a variety of metals, making it suitable for a vast array of applications. Its ability to produce large, heavy parts also makes it ideal for industries that require robust components.

Conclusion

In conclusion, understanding the intricacies of sand casting pricing is essential for those involved in manufacturing and procurement. By analyzing factors such as material costs, complexity, size, production volume, labor, and lead times, businesses can make informed decisions that align with their operational needs and budgetary constraints. Despite varying prices, sand casting continues to be a reliable and effective method for creating high-quality metal parts, proving its value across many sectors.

Post time:តុលា . 08, 2024 11:26

Next:砂型鋳造に使用される砂のタイプ。