The Future of Sand 3D Printing Innovations and Applications

In recent years, 3D printing technology has revolutionized various industries, providing innovative solutions that were previously unimaginable. One of the most exciting advancements in this field is sand 3D printing. This technique utilizes sand as a primary material and has opened up new frontiers in manufacturing, construction, and art.

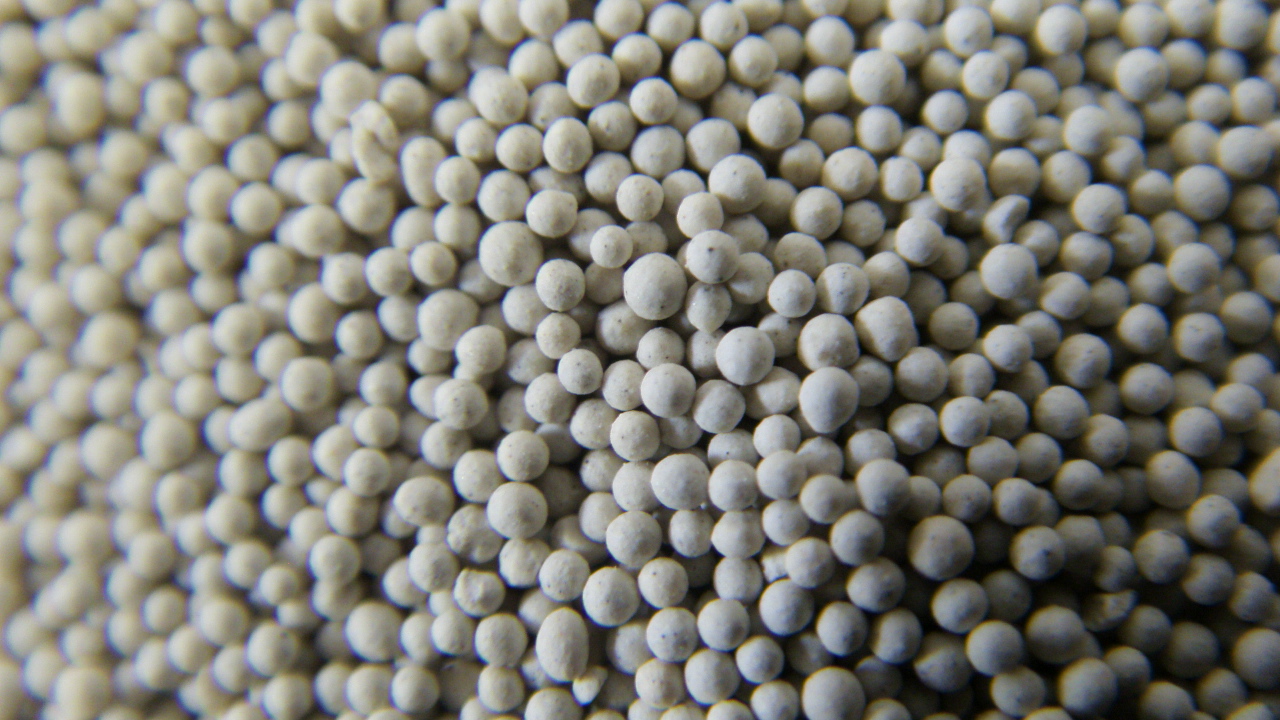

Sand 3D printing is primarily based on binder jetting technology, where a specially designed printer deposits a binder onto sand particles to create objects layer by layer. This method allows for the production of intricate designs that can be both functional and aesthetic. The process begins with a digital 3D model, which is sliced into thin horizontal layers. The printer then lays down a layer of sand, followed by applying the binder in the desired pattern. This cycle repeats until the entire object is formed, which can then be cured or finished to enhance its structural integrity.

The Future of Sand 3D Printing Innovations and Applications

In the construction industry, sand 3D printing has the potential to transform how we build homes and infrastructures. With the ability to create large-scale structures efficiently, this technology can address housing shortages and provide quick, sustainable solutions in disaster-stricken areas. For instance, companies like ICON have already demonstrated the feasibility of 3D-printed homes, which are built using a cement-like material. However, the potential for using sand-based materials to craft durable, weather-resistant structures is an even more promising avenue, particularly in coastal areas where sand is plentiful.

sand 3d print

Another noteworthy application of sand 3D printing is in the field of art and sculpture. Artists can leverage this technology to create complex, detailed artworks that would be incredibly challenging to achieve by hand. The precision of sand 3D printing allows for unique textures and forms that can capture the imagination and evoke emotion. Moreover, artists can experiment with different types of sand and binders to achieve various effects, making this an exciting medium for contemporary art.

Furthermore, the casting industry stands to benefit significantly from sand 3D printing. Traditionally, creating molds for metal casting can be a time-consuming and costly process. Sand 3D printing allows for rapid prototyping of complex molds, reducing lead times and production costs. This capability is crucial in industries like automotive and aerospace, where precision and speed are paramount.

As technology continues to evolve, the future of sand 3D printing looks promising. Innovations in materials science and printing techniques will likely enhance the efficiency and applicability of this technology, enabling even more complex designs and faster production times. As sustainable practices become increasingly important in our modern world, sand 3D printing stands out as a pioneering solution that combines efficiency, creativity, and environmental stewardship.

In conclusion, sand 3D printing is at the forefront of a manufacturing revolution, offering unique opportunities across various sectors. Its applications in construction, art, and industry promise to redefine how we perceive and interact with our built environment. As we move forward, it’s essential to embrace these innovations and explore the boundless possibilities they present.

Post time:តុលា . 12, 2024 00:44

Next:types of sand in foundry