The Art of Sand Casting A Timeless Manufacturing Technique

Sand casting, one of the oldest manufacturing processes known to humankind, continues to play a crucial role in modern industry. This technique, which dates back thousands of years, involves creating objects by pouring molten metal into a sand mold. Its remarkable versatility, cost-effectiveness, and simplicity make it a preferred choice for many applications across various sectors.

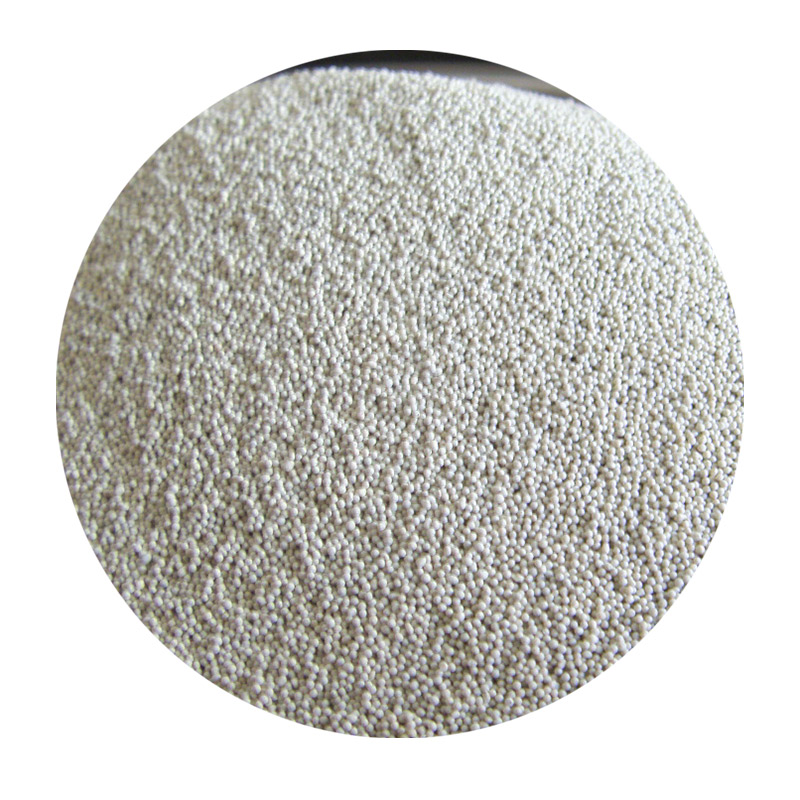

At the heart of the sand casting process lies a mixture of sand, clay, and water, which is used to create a mold. The sand is typically fine and has excellent binding properties, allowing it to retain its shape when compacted around a pattern that represents the final object. This pattern, usually made of metal, wood, or plastic, is a replica of the product to be cast. Once the pattern is set within the sand mixture, it is carefully removed to create a hollow cavity that will form the final piece.

The preparation of the sand mold is critical. A properly compacted mold ensures the integrity of the final casting, minimizing defects such as porosity or misalignment. Once the mold is ready, molten metal—often aluminum, iron, or bronze—is poured into the cavity. The temperature of the molten metal is crucial, as it must be high enough to flow smoothly into the mold but not so high that it causes undue stress on the mold itself.

sand cast

After the metal has cooled and solidified, the sand mold is disassembled, revealing the cast object

. This initial casting often requires further machining and finishing to achieve the desired specifications and surface quality. Despite these additional steps, sand casting remains one of the most economical methods of producing components, particularly for large parts or low to medium production runs.One of the most significant advantages of sand casting is its adaptability. It can be used to create a wide range of shapes and sizes, from intricate details in jewelry to large components in automotive and aerospace industries. Furthermore, the environmental impact of sand casting is relatively low compared to other methods, as it often uses recyclable materials and produces less waste.

In conclusion, sand casting is a time-honored technique that continues to thrive in today’s manufacturing landscape. Its ability to produce complex shapes at a relatively low cost, combined with its versatility and sustainability, ensures that it will remain an essential process for years to come. As technology advances and industries evolve, sand casting will undoubtedly adapt, continuing to meet the needs of modern production challenges.

Post time:សីហា . 31, 2024 07:30

Next:Golden Sand | Your Ultimate Beach Destination