How Does Sand Casting Work?

Sand casting is a widely utilized manufacturing process that enables the creation of complex metal parts through the use of sand molds. This method, known for its versatility and cost-effectiveness, is ideal for producing both simple and intricate shapes used in various industries such as automotive, aerospace, and art.

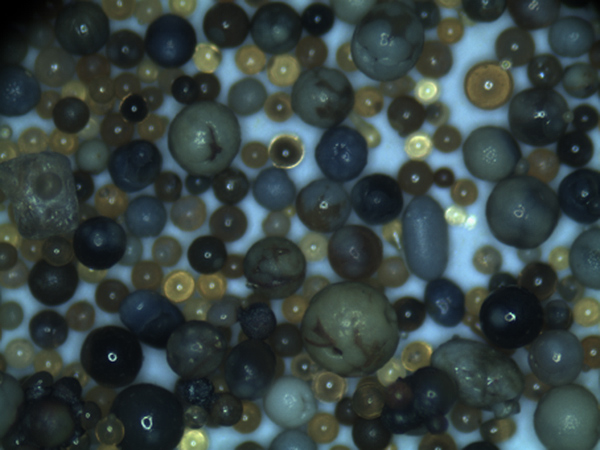

The process begins with the preparation of the sand. Specially formulated sand, typically a mixture of silica, clay, and water, is used to form the mold. This mixture provides the right balance of strength and flexibility, crucial for creating detailed impressions of the desired part. To ensure that the mold captures the intricacies of the design, the sand must have appropriate binding and cohesion properties.

How Does Sand Casting Work?

Once the mold is prepared, the next step is melting the metal. The type of metal used varies depending on the application but commonly includes cast iron, aluminum, or bronze. The metal is heated in a furnace until it liquefies. It is critical to achieve the right temperature to ensure a proper pour and to avoid defects in the final casting.

how does sand casting work

After the metal reaches the desired temperature, it is poured into the mold cavity. This step requires precision; pouring too quickly can lead to splashing or air entrapment, while pouring too slowly might result in premature solidification. The molten metal fills the space left by the pattern, taking on its shape as it cools and solidifies. Depending on the specifications, cooling times can vary, and some castings may require additional care, such as heat treatment, to meet mechanical property requirements.

Once the metal has cooled sufficiently, the sand mold is broken away to reveal the casting. This is where the unique characteristics of sand casting shine, as it allows for complex geometries and intricate designs. However, the surface finish of castings produced through sand casting is typically rougher compared to other methods, like investment casting, necessitating further machining to achieve the desired finish and tolerances.

Following the removal of the casting, it undergoes several secondary processes such as trimming, machining, and finishing to prepare it for final use. Any excess material, known as flash, is also removed during this stage.

In conclusion, sand casting is a valuable process that combines traditional techniques with modern manufacturing practices. Its adaptability is one of its strongest attributes, allowing for the production of high-quality, durable components used across numerous sectors. Understanding how sand casting works provides insight into its significance in the production of small to large-scale metal components, ensuring its continued relevance in the industry.

Post time:វិច្ឆិកា . 19, 2024 03:02

Next:resin coated sand suppliers