Understanding Foundry Sand Composition A Key Element in Metal Casting

Foundry sand is an essential material used in the casting process of metals, serving as a mold and core material. The composition of foundry sand significantly affects the performance and quality of metal castings, making it crucial for foundry professionals to understand its various components and their implications.

Types of Foundry Sand

Commonly used foundry sands include silica sand, olivine sand, and zircon sand. Silica sand, composed primarily of silicon dioxide (SiO2), is the most prevalent type due to its availability and cost-effectiveness. Olivine sand, derived from a natural mineral, offers excellent refractoriness and is often used in high-temperature applications. Zircon sand, though more expensive, is appreciated for its low thermal expansion and ability to produce detailed molds.

Key Components of Foundry Sand

1. Silica Content The most critical component of foundry sand is its silica content. High purity silica (greater than 95% SiO2) is ideal for most casting applications. It provides structural stability during the casting process and is resistant to thermal shock. However, the grain size and shape of silica particles also play a vital role in the sand's performance. Rounder grains tend to flow better, creating smoother molds, while angular grains offer better interlock, improving strength.

2. Fines The presence of fines, or smaller particles, within the sand mixture can significantly impact mold quality. A balanced proportion of fines can enhance mold strength and surface finish. However, excessive fines may lead to problems such as poor airflow and difficulty in mold release. Therefore, careful grading and screening of sand are necessary to achieve optimal results.

3. Additives Various additives may be mixed with foundry sand to improve its properties. For instance, binding agents are often added to enhance the strength and durability of molds. Common binding agents include bentonite clay, which helps retain moisture and improves the sand's ability to hold shape. Other additives may be used to enhance specific qualities, such as anti-strip agents to prevent defects when the molds are removed.

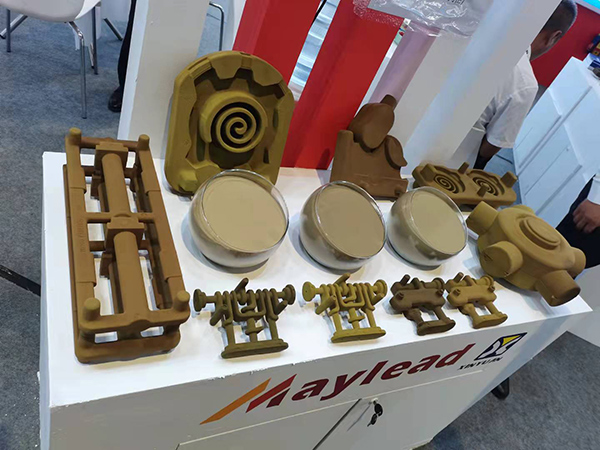

foundry sand composition

4. Moisture Content The moisture level in foundry sand can affect its workability and the final casting quality. Sand with too much moisture may lead to casting defects such as vapor defects, while insufficient moisture can result in a weak mold structure. Proper control of moisture content is critical, often requiring the use of moisture meters and controlled storage environments.

Testing Foundry Sand Composition

To ensure the suitability of foundry sand for specific applications, various tests are conducted. These may include

- Grain Size Analysis This determines the distribution of particle sizes in the sand, which is critical for predicting mold behavior and finishing properties. - Chemical Analysis This assesses the composition of sand to confirm that it meets the required specifications for silica content and the presence of impurities. - Moisture Content Tests These measure the amount of moisture present in the sand, ensuring it falls within the ideal range.

The Importance of Foundry Sand Composition in Casting Quality

The composition of foundry sand directly correlates to the quality of the final cast product. Poor quality sand can lead to numerous defects, including rough surfaces, dimensional inaccuracies, and reduced strength. On the other hand, a well-graded, properly composed sand mixture can facilitate the production of high-quality, intricate castings, ensuring longevity and performance.

Conclusion

In conclusion, the composition of foundry sand is a complex but crucial aspect of the metal casting process. By carefully selecting the types and proportions of materials used in sand mixtures, foundries can significantly enhance the quality of their castings. Advancements in sand testing and preparation technologies continue to improve the industry’s ability to produce high-quality products that meet modern manufacturing standards. Therefore, understanding and optimizing foundry sand composition remains a fundamental practice for achieving excellence in metal casting.

Post time:តុលា . 11, 2024 22:35

Next:Techniques for Smoothing 3D Printed Models Through Effective Sanding Methods